Versatile and effective food cutting: up to 1,500 kg per hour in perfect quality

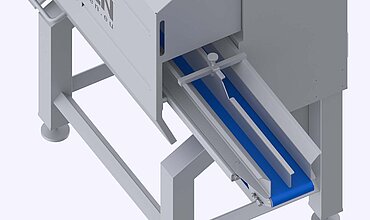

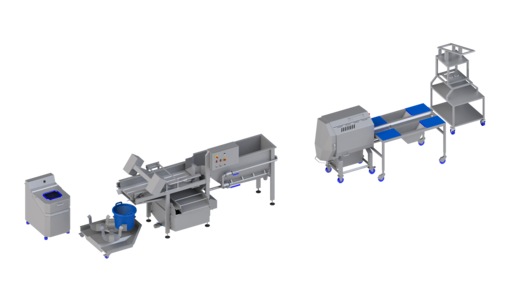

The GS 10-2 is a belt cutting machine for slicing, grating, rasping and dicing and is one of KRONEN’s flagship models. The multifunctional belt slicer allows users to cut virtually all kinds of food: salad leaves, vegetables, fruit, herbs, meat, cooked meat, fish, vegan substitutes, baked goods, cheese and nuts. This makes it ideally suitable for an extremely wide range of applications and sectors. Depending on the product and cutting type, the GS 10-2 processes up to 1,500 kg of product per hour.

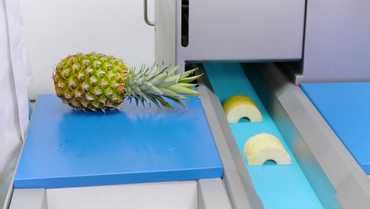

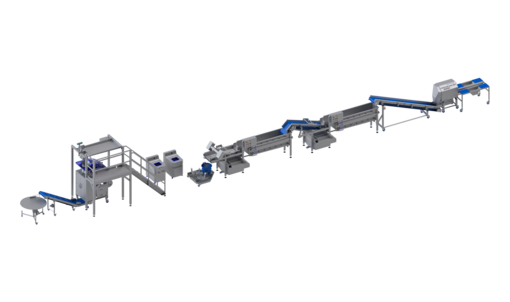

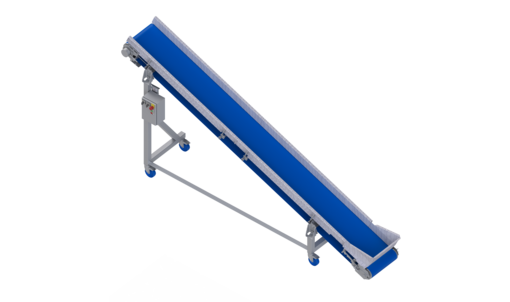

Prior to processing, the right knife for the product is installed; no tools are required for this purpose. The cutting thickness is infinitely adjustable from 0.5 to 50 mm. The hold-down pressure and the knife and belt speed are then set. The product is prepared for cutting, e.g. cored, peeled or segmented, before being placed on the 125 mm-wide infeed belt depending on the cut intended. Next, it is cut precisely and gently thanks to precise hold-down technology and product guidance. As standard, the cut product can be ejected underneath the knife box, for example into a spin basket or a Euro crate. It can be optionally conveyed via a discharge belt for further processing, for example when the GS 10-2 is integrated into a processing line.

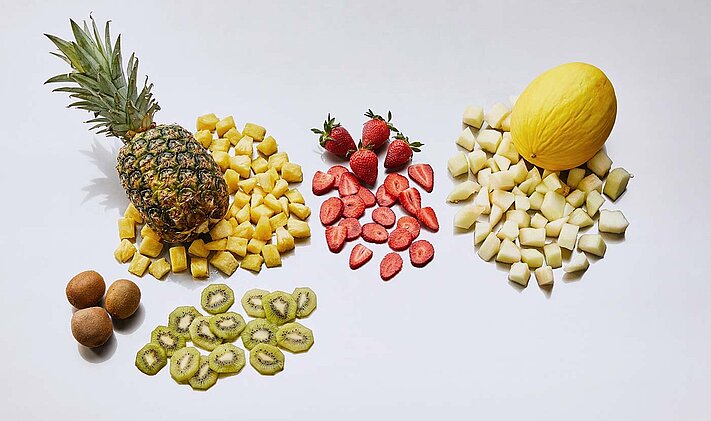

Versatile application options:

The cutting machine can be used flexibly for various applications, for example:

- Cutting lettuce, e.g. iceberg lettuce, into strips or shreds

- Cutting lollo rosso lettuce into pieces

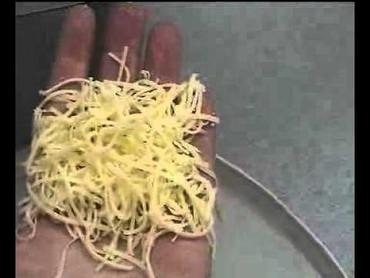

- Cutting cabbage into strips or shreds

- Grating carrots or cutting them into sticks or slices

- Dicing potatoes

- Dicing pineapple and mango

- Cutting cooked chicken breast into slices

- Cutting cabanossi or bockwurst sausage into slices

- Cutting cooked meat into strips or pulling it apart to make "pulled beef"

- Cutting, dicing or shredding fish, for example salmon

- Cutting or shredding vegan meat substitutes

- Grating hard cheese

- Cutting or dicing bread rolls or baguettes

- Grating nuts

The GS 20 belt cutting machine is suitable for products wider than 12 cm. It has a 250 mm-wide infeed belt and processes up to 4,000 kilograms per hour.