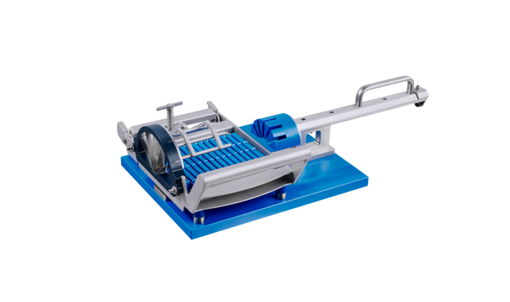

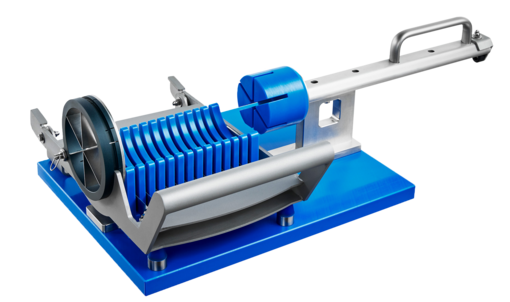

Versatile and particularly user-friendly

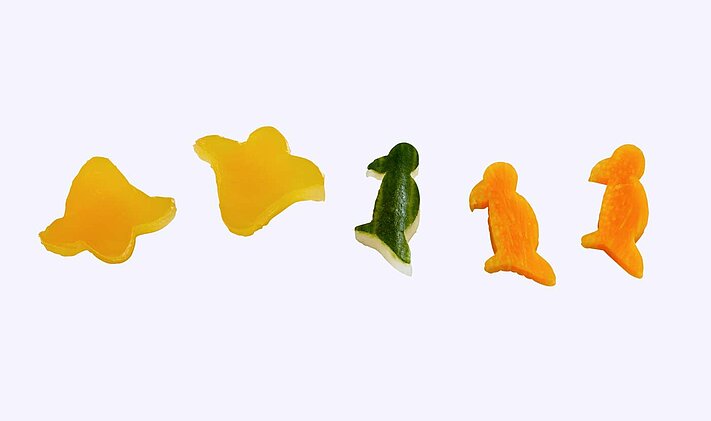

The manually operated HGW grid cutter can be adapted for processing a variety of different products thanks to the multitude of cutting inserts available. It is suitable for various application options and cuts, peels, punches and cores fruit, vegetables and lettuce. In addition to the standard cutting types – slices, cubes, sticks, chunks or segments – many inserts are also available for special punching forms, for example corers for cabbages or peppers, cutters for kiwis or cauliflowers and mango pitters. With the inserts for cutting to length, peeling, coring and slicing, an extremely wide variety of products such as pineapple or cabbage can be processed efficiently. Inserts are also available for special cuts such as diamonds, boats and disks in various sizes, as well as decorative shapes (stars, hearts and many more).

The grid cutter is particularly easy to operate and has very low maintenance requirements, thus making it extremely user friendly. The optimized version of the HGW enables tools to be changed even faster, and its adapted design facilitates operation requiring less effort and achieves reduced wear and user-friendly accessibility for even easier cleaning. The lifting height has been increased to 270 mm to allow for the processing of higher products, with a maximum height of 155 mm (when using the pineapple cutter) or up to 270 mm (when using the dicing grid or segment divider) possible depending on the cutting insert used.

The product to be processed is positioned manually on the HGW. When the lever is pulled down, the product is cut into the corresponding shape according to the knife used. The cut product falls down – either into a prepared container or onto an optionally available conveyor belt.

In the standard version, the HGW is a tabletop device; a mobile base frame is optionally available.