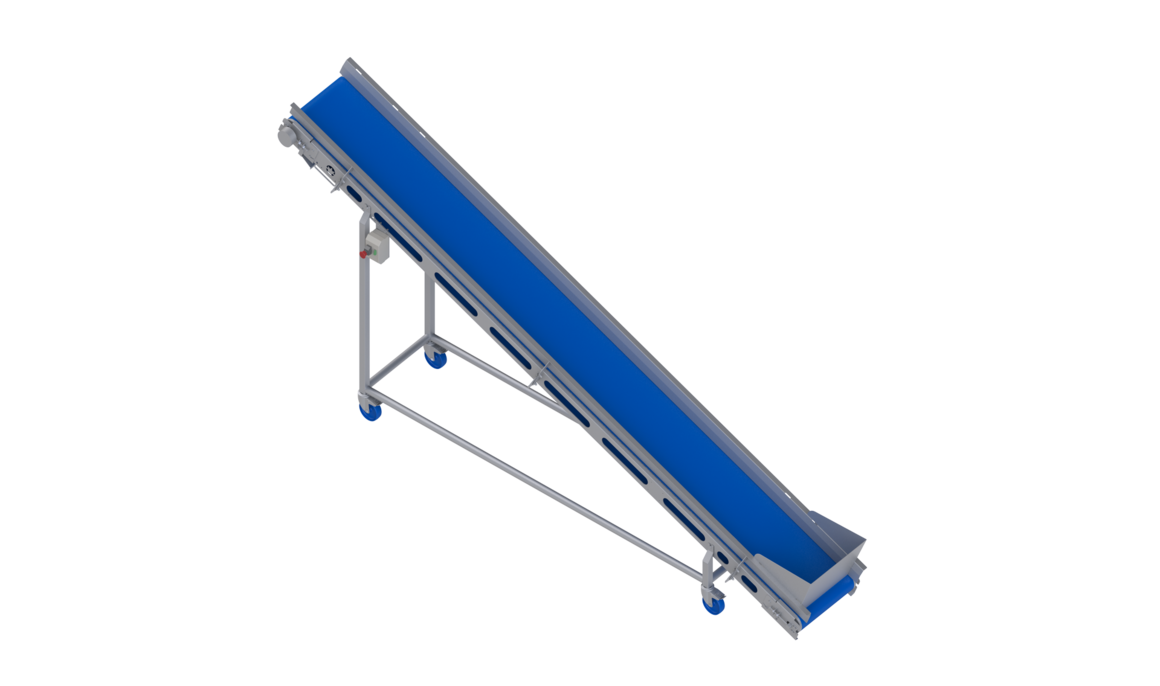

Cost-reduced conveyor belt: flexibly adaptable to different food products and requirements

The ECO conveyor belt enables the continuous transport of food products (cut and whole) to the next processing step, for example to the peeling or cutting machine, and from here to the washing machine. Among other things, it is also suitable for the discharge of waste products.

The belt is available in a wide variety of designs and can be individually customized to meet specific requirements in the food industry. A hopper for product infeed is included and can be adapted to the machine or product used in each case. The belt also comes with a mobile base frame and, in the case of smooth belts, a scraper.

Compared to theConveyor PLUS, the ECO version is always suitable when the conveyor belt does not need to be removed, for example in order to be submerged in a cleaning solution. Due to the quick tension relief function, the ECO conveyor belt can be manually cleaned very well from all sides. The side guides can be folded down and the hopper is removable.