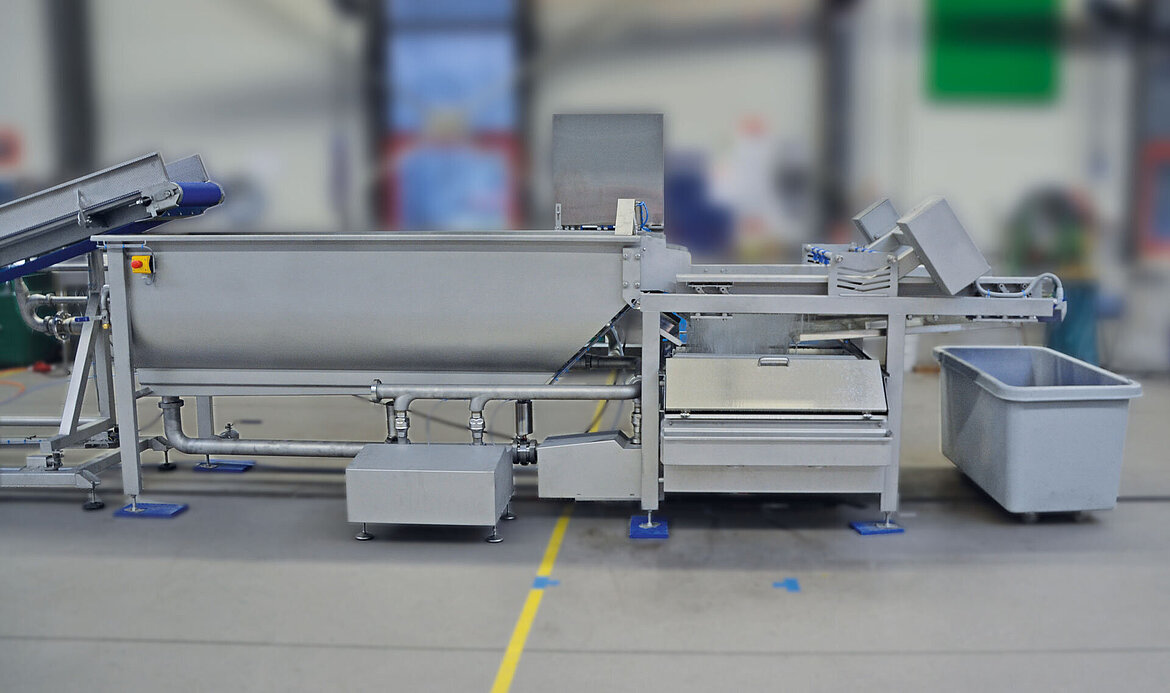

Efficient washing of whole or halved products using cleaning agents with the GEWA 4000V RT:

Customising and adapting machines to a customer´s special processing requirements is one of KRONEN's key competencies.

By integrating a retention time function in the GEWA 4000V RT (RT stands for “Retention Time”) KRONEN has optimised the requirements of customers who process whole or halved products. Currently a second GEWA 4000V RT has been completed and delivered within just a few months.

This washing machine has a time controlled retaining flap which automatically controls the retention time of the products in the wash tank. This means when using cleaning agents, the fully adjustable contact time a product has with water can be guaranteed. This is a fundamental step for hygiene in further processing.

To facilitate the ideal washing process the product is weighed before it is fed into the machine to ensure that always the same quantity is processed. This avoids overfilling the tank which would hinder a thorough wash-cycle. Simultaneously it ensures an efficient, continual use of the machine. For example, up to 500 kg courgettes, halved peppers or peeled onions can be washed per hour. The cleated belt enables smooth product infeed particularly for whole or bigger products or product pieces.

The further development of the GEWA 4000V enhances the range of GEWA washing machines which process whole products or larger product pieces with the aid of cleaning agents. Any of the washing machines from the GEWA series can be equipped with the RT adjustable retention time function. Currently two GEWA 4000V RT machines are delivering perfect washing results in the production of two customers in the convenience and food service sector.