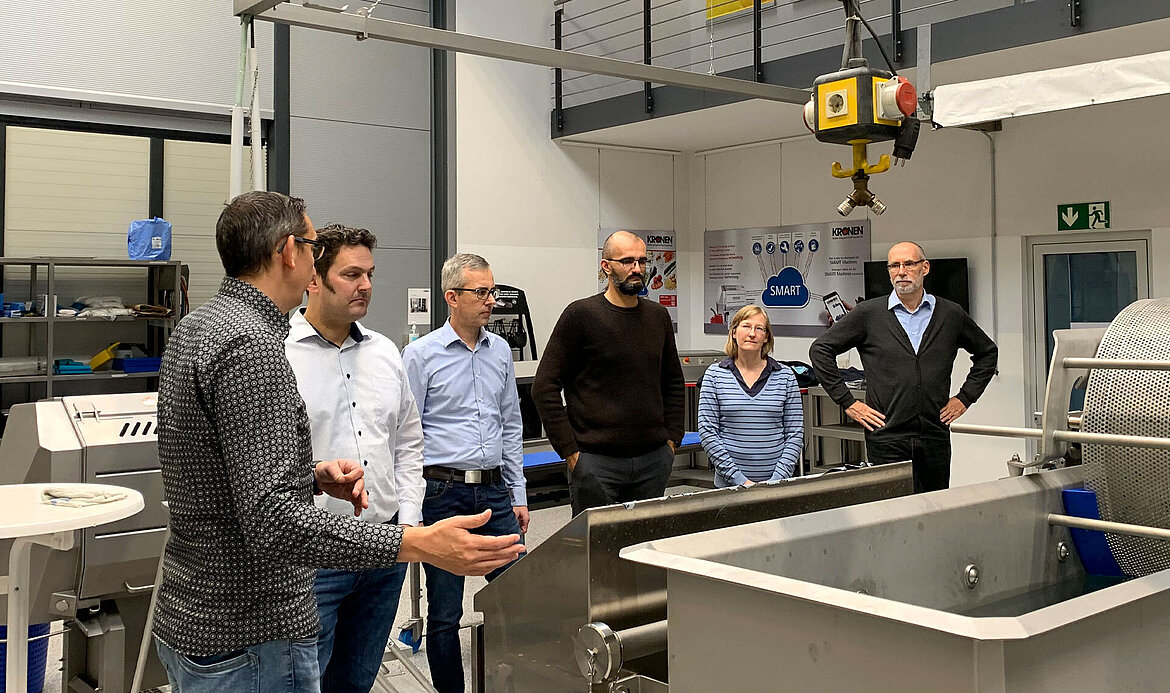

Meeting of the partners from the SPLASH research project in Kehl:

As part of the project, KRONEN is working with scientific partners, those from the industry and in practice to develop an innovative washing process for fresh cut lettuce. At this project meeting at KRONEN, a washing machine specially adapted for this decontamination process was now tested.

The initial point of the research project is to prevent the risk of microorganisms from contaminating packed cut lettuce. Commonly, cell sap released from freshly cut lettuce combined with humidity (unavoidable in plastic packaging) provides a breeding ground for microorganisms.

The project team works on a resource-saving washing process for cut lettuce using a non-thermal plasma procedure. Hygienic treatment of the lettuce prevents premature spoilage therefore increasing consumer safety. Furthermore, the process is particularly gentle.

The tests that were carried out during the Project Meeting in Kehl were very successful. The participants from the Leibniz Institute for Agricultural Engineering and Bioeconomics (ATB Potsdam), the company Gartenfrisch Jung GmbH and the Leibniz Institute for Plasma Research and Technology e.V. (INP Greifswald) put into operation the washing machine, which had been specially adapted to the hygienizing washing process, and tested it with cut iceberg lettuce.

The next step in the project sees an extensive testing phase actually in the production line of one of the project members Gartenfrisch Jung, manufacturer of fresh-convenience. Here the focus is on the study of the disinfection efficiency in the wash water, the conservation of resources and the optimisation of transport and shelf life of the products.

The project sponsor of the research project is the German Federal Agency for Food and Agriculture. Funding is provided as part of the programme to promote innovation of the Federal Ministry for Food and Agriculture.