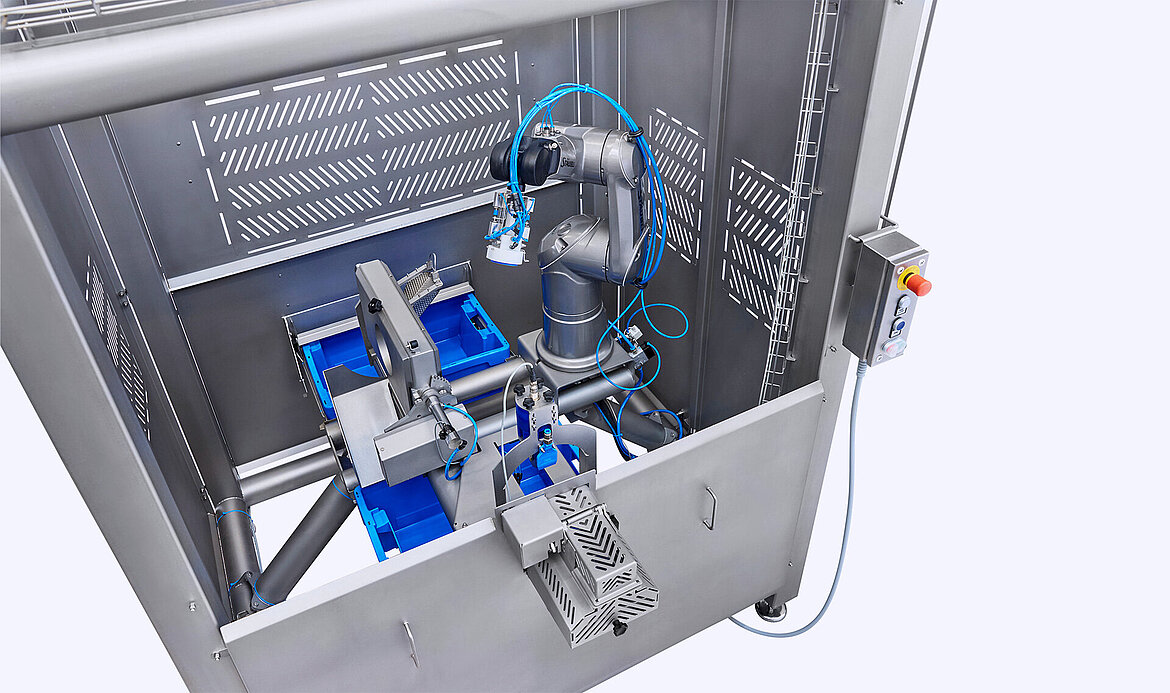

The innovative Robot Avocado Line adds automation to avocado processing

The growing popularity of avocados and the resulting increase in the quantities of avocados harvested and processed are currently posing new challenges for the food industry. KRONEN GmbH reacted to this new trend by developing an innovative Robot Avocado solution, which has now completed a successful test phase at a customer facility in the Netherlands.

Over a period of several weeks, the company Lazy Foods , a manufacturer of clean-labelguacamole and avocado spreads based in the Netherlands, used the Robot Avocado Line to pit and peel avocados under real production conditions. KRONEN’s innovative solution for the automated processing of the sensitive fruit was presented for the first time at this year’s Fruit Logistica and Anuga FoodTec exhibitions.

Patented tools for gentle processing

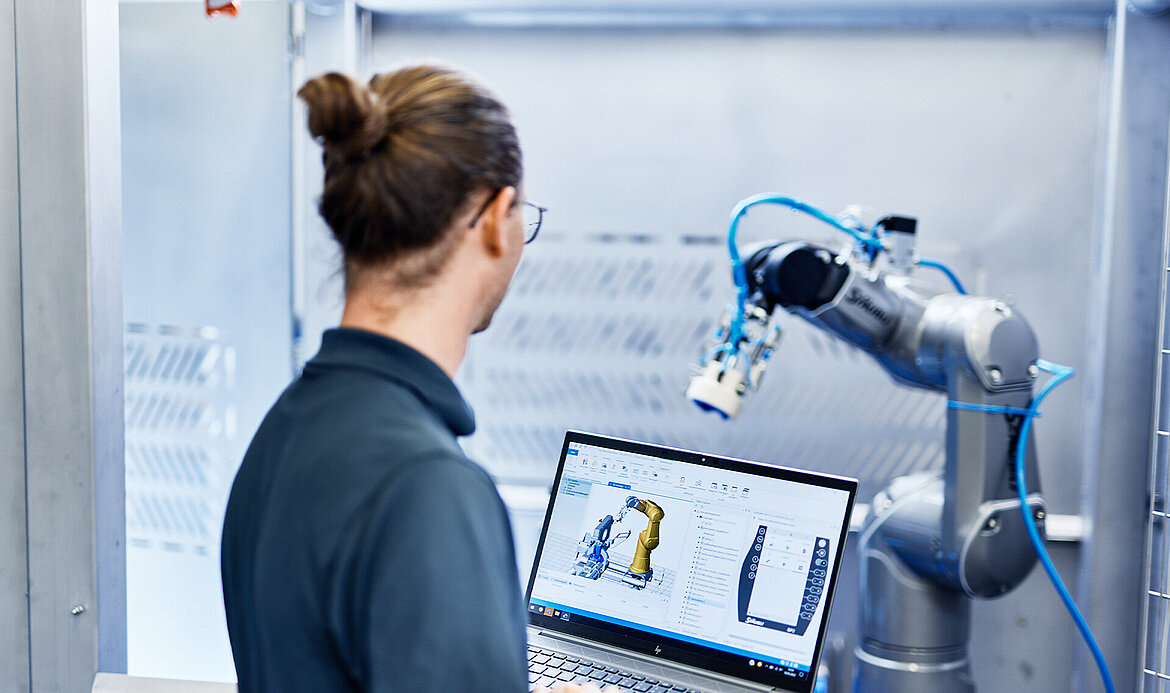

The Robot Avocado Line stands out by using KRONEN’s patented tools and methods for halving, pitting and peeling avocados in combination with a robot suitable for food processing from the manufacturer Stäubli. The tools and processes are specially adapted to cater to the special requirements of avocados and thus achieve a very high yield when peeling the fruit. The line can process up to 400 avocados per hour with one robot, but its productivity can also be increased to up to 1,000 avocados per hour by using two to three robots. According to user data, the line pays for itself within just over a year.

Automation as the key to efficiency

During the test phase under real production conditions at Lazy Foods, a company specializing in the production of high-quality avocado spreads containing no additives, a number of small optimizations have already been made to the robot line directly on site. The suction grabber, for example, has been adjusted to hold smaller fruits or fruits with very uneven skin in cooperation with the German Institute of Food Technology (DIL), which was already involved in the development of the grabbing technology within the scope of a research project. The team at Lazy Foods was extremely pleased with the line’s processing results with ready-to-eat avocados. To tackle the challenges faced in the case of harder fruits, the KRONEN team worked together with Lazy Foods to further develop the processing solution.

The Lazy Foods team initially assigned 6 to 10 employees to handle the semi-automatic avocado processing with the current KRONEN Convenience Avocado Line. However, the manual peeling process led to joint pain in some employees, and the increasing staff costs and difficult search for employees triggered the search for a solution with the highest possible degree of automation.

A successful practical test in an industrial setting

The robotic solution helps to improve the efficiency of avocado processing and combat the challenges of the staff shortage and higher staff costs. Lazy Foods therefore provided very positive feedback on the overall concept of the line, its high degree of automation while maintaining a constant yield and the excellent cooperation with KRONEN and Synergy Systems, KRONEN's representative in the Netherlands. KRONEN worked in close consultation with Lazy Foods to solve the challenges arising from the very different sizes of avocado fruits and their varying degrees of ripeness in industrial processing. As a result, it was able to increase the line’s tolerance for the differences in the products being processed. This continuous support and problem-solving cooperation underline KRONEN’s commitment to continuously further developing and upgrading both this solution and future innovations.

About Lazy Foods B.V.

Lazy Foods is a Dutch manufacturer, specialized in chilled, freshly, all natural made Avocado products without the use of any preservation by applying High Pressure Processing (HPP). In their new and State of the Art production facility in Ridderkerk, The Netherlands, a range of products is produced for the Dutch market, like Guacamole and many other Avocado blends. Lazy Foods is also exporting their products throughout Europa to retail, food service and leisure companies.

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product portfolio of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging.

KRONEN additionally offers machines for the processing of meat and fish, special vegan products, baked goods and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide and supplies its products to more than 120 nations all over the globe.

With more than 45 years of experience in food technology, KRONEN prides itself on its quality awareness and constantly strives to achieve the best possible solutions in its day-to-day work. The machine manufacturer focuses on taking a sustainable, holistic approach toward the hygienic, reliable and resource-friendly production of fresh foods. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.