Perfect avocados: absolutely reliable, hygienic and efficient pitting, halving and peeling – up to 1,000 pieces/hour

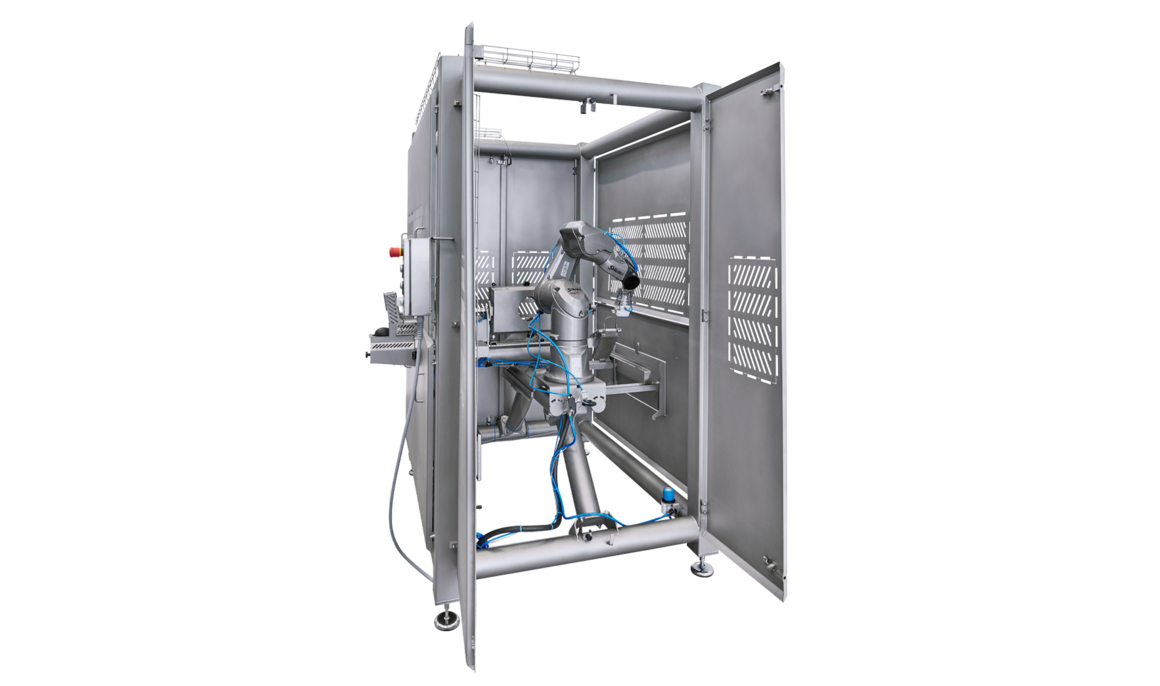

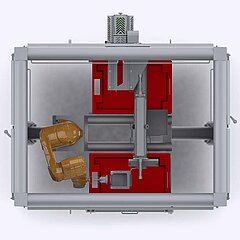

A special robotics solution was developed for the automated avocado processing line. It is used for peeling, halving and pitting avocados gently and efficiently at the same time.

The avocados are placed in an inlay tray by an employee. The individual processing steps are then carried out fully automatically by the robot(s):

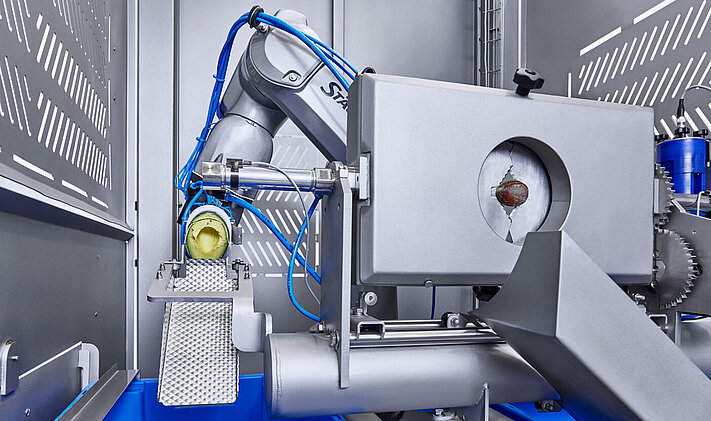

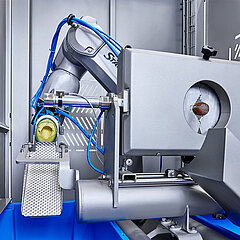

- The robot removes the avocado with a gripper specially adapted to the fruit and pits the first half by means of a rotating movement on a pitting unit.

- The knives cut the flesh in half and clamp the stone.

- The avocado is then peeled. The robot separates the shell from the pulp by moving over the peeling knife.

In the system with a robot, the second avocado half is now pitted and also peeled. Then the cycle starts all over again. At the exit point, another person checks for shell and stone residues as well as natural damage to the product. Good products can be collected in boxes or discharged via a belt, depending on capacity and customer requirements.

The processing technology used is patented: equipment and method for halving, pitting and peeling avocados gives you a unique technical advantage.

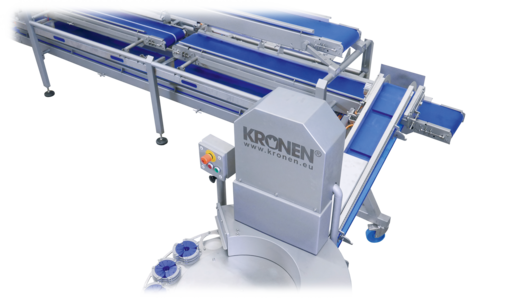

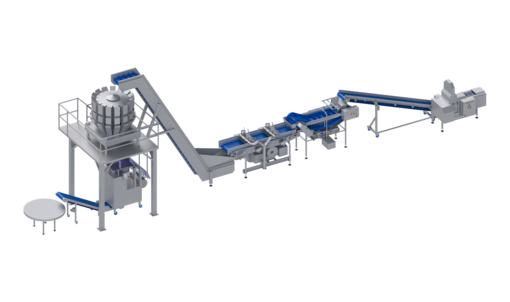

Optionally, a GS 10-2 belt cutting machine can be added to the line to further process the avocados into cubes or slices.

Benefits of the robotics solution:

- High reliability

- Temperature independence

- Maximum hygiene

- Flexible use

- Ability to plan capacities

Stäubli robots are integrated, which can be optimally cleaned thanks to the specially treated surface. The system is separated by a safety enclosure. Each KRONEN robotics solution receives its own risk assessment with a CE marking before delivery. This ensures that the facilities optimally guarantee the safety of the personnel.

KRONEN’s robotic systems also feature the option of remote maintenance. This means that the customer can be supported directly and quickly by the KRONEN Service Team if required.

Application options and capacities:

The system is designed for processing avocados but can also be adapted to process medium quantities of various other types of fruit.

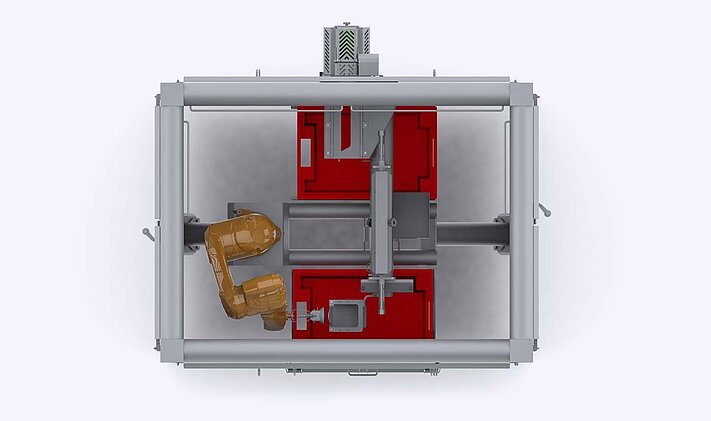

Depending on the capacity required, several robots can be used simultaneously:

- up to 400 pieces/hour with one robot

- up to 800 pieces/hour with two robots

- up to 1000 pieces/hour with three robots

- Any amount of further extension possible

To be suitable for processing, the avocados must have a degree of ripeness that corresponds with a pressure value of up to 3.5 kg (measured using a fruit penetrometer with an 8 mm tip).