Perfect avocados in large quantities: pitting, halving and peeling up to 4,800 pieces/hour.

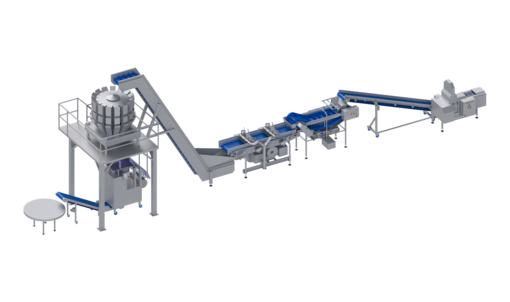

The semi-automated Convenience Avocado Line is a specially developed solution for peeling, halving and pitting large quantities of avocados gently yet efficiently, making processing easier for personnel and increasing productivity per person to the maximum. The ergonomic tools prevent wrist strain during pitting and peeling. This is because the rotating movement that is necessary when processing manually with a knife or spoon would otherwise lead to injuries when processing large quantities.

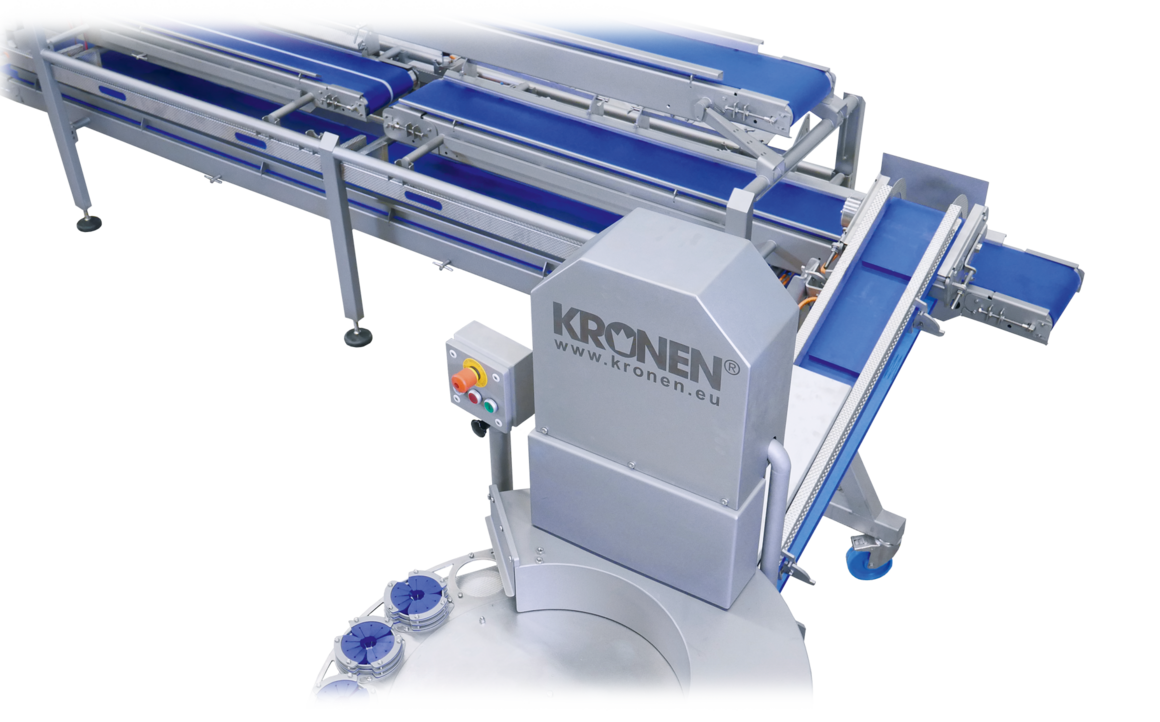

The following machines or solutions are integrated into the line:

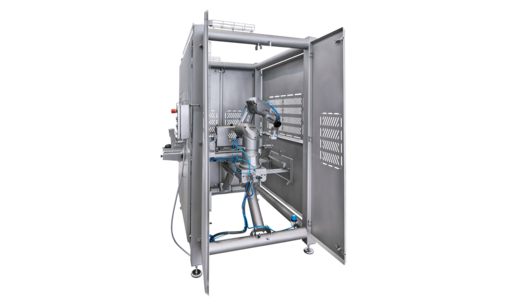

- Cutting: TONA S180K cutting machine or Tona Rapid with an infeed belt for halving avocados

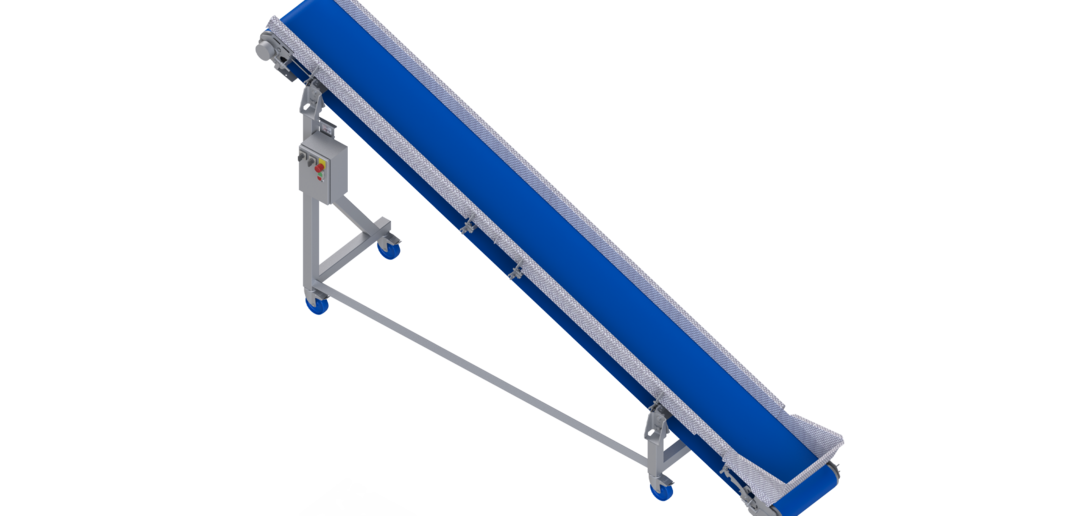

- Conveying: PLUS inclined conveyor belt

- Preparation: Processing station (in combination with the TONA S180K cutting machine, the station is designed for nine people as standard; if the Tona Rapid is integrated as an alternative, it is correspondingly larger) with several workstations and each with

- a conveyor belt, outfeed and waste belt

- specially developed tools for pitting and peeling avocados

Optionally, a GS 10-2 belt cutting machine can be added to the line to further process the avocados into cubes or slices.

Application options and capacities:

The system is designed for processing avocados but can also be adapted to process medium quantities of various other types of fruit.

Capacity with TONA S180K:

- up to 1,200 pieces/hour

- approx. 300 kg raw product mass/hour

- Approx. 165 kg finished product/hour

Capacity with Tona Rapid:

- up to 4,800 pieces/hour

- approx. 1,200 kg raw product mass/hour

- approx. 660 kg finished product/hour

The end product and waste product are automatically separated at the processing station via the outfeed and waste belt.