Precise and consistent cutting quality with versatile processing options

The TT450 is designed for professional use in the preparation area of automated lettuce processing. The TT450 is a top and tail machine for automatically trimming the stalk and leaf tips of frisée, endive and romaine lettuce or all green lettuces with flat stalks. The TT450 allows a considerable increase in productivity by up to 110 % per person compared to manual processing, as well as an improved yield of up to 6 % more at the same time.

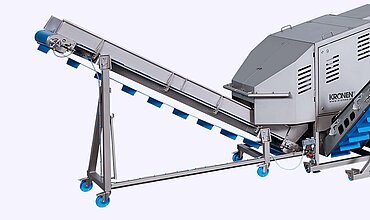

The TT450 is equipped with an automatic waste sorting system, which can optionally be supplemented with additional discharge and waste belts.

The robust industrial design and the open construction with a removable cover and easily opened hinged doors enable quick and easy cleaning and thus optimal hygiene.

The machine is characterized by its intelligent operation, which is also very simple and safe:

- The lettuces are transported to the cutting unit via a chain-based infeed belt and held in an optimal cutting position by gentle hold-down technology.

- In the infeed area, an adjustable product guide plate, positioned at an angle to the cutting point, is installed to ensure that each product is cut to the same length on the stalk side. The product infeed speed is adjustable and can therefore be adapted to meet customer requirements. The position of the knives can be adjusted to optimally adjust the yield to suit different raw materials or requirements. The adjustment of the knife positions takes place via a manual crank and can be adjusted in a controlled manner via a scale.

- The stalk and leaf tips (may be necessary in case of dry leaf tips or brown discoloration) are removed in one step, and the cutting lengths of the stalk (10–60 mm) and leaf tips (120–450 mm) are variably adjustable.

Either both functions can be carried out together or only the coring procedure can be selected. - Waste chutes guide the waste onto a waste belt (optional) positioned horizontally underneath the machine as standard and return it to the intake area at the rear of the machine. The good product falls out of the product holders at the turning point of the product infeed and can be forwarded for further processing with an optionally available discharge belt.