The US-based company that contracted KRONEN to supply the new line processes all kinds of fresh fruit and vegetables and supplies its products to customers such as restaurants, hotels, catering establishments, wholesalers and retailers. The new solution was recently approved by the company and has now been shipped to the USA.

The processing line can be used to trim, destem, divide and wash broccoli and cauliflower. It comprises the following solutions:

- A special trimming table with three KRONEN infeed belts, at which the product can be prepared manually if required. One conveyor belt is used to feed the raw produce into the machine, another discharges the trimmed product, and the third belt transports the waste away from the line

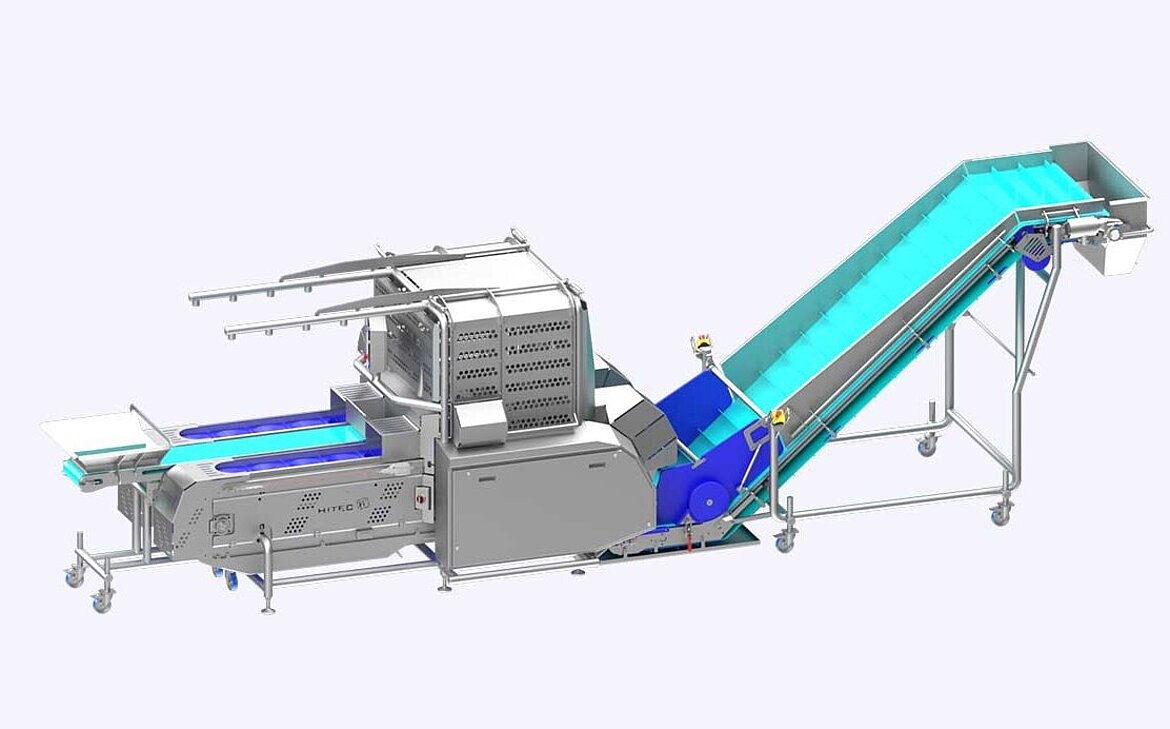

- The DCM TWIN decore and cutting machine with an infeed and discharge belt from the KRONEN partner Hitec, which first destems the broccoli or cauliflower and can then cut it into two, four or eight pieces

- An additional special trimming table at which the product is checked and undergoes final treatment

- A GEWA 5000 PLUS HELICAL washing machine with vibration outfeed for washing the finished cauliflower or broccoli florets

If the fresh-cut processor receives products that have already been prepared, it can feed them directly into the DCM TWIN or onto its infeed belt to further increase the capacity.

The new line enables the company to process up to 6,000 heads of broccoli or cauliflower per hour.