The global market for meat substitutes is growing rapidly, and the demand for efficient and safe processing solutions for alternative sources of protein is increasing. For a customer based in the USA, KRONEN has now developed a customized line for processing sunflower seeds.

Sunflower seeds can be used to produce a high-quality plant-based protein suitable for use as a meat or milk substitute. Together with the KRONEN branch in the USA and a customer, the KRONEN team recently developed a line for washing and soaking sunflower seeds. The SMARTe line enables quality and process-related data to be evaluated by networking communication-enabled machines and transferring data to a database in real time.

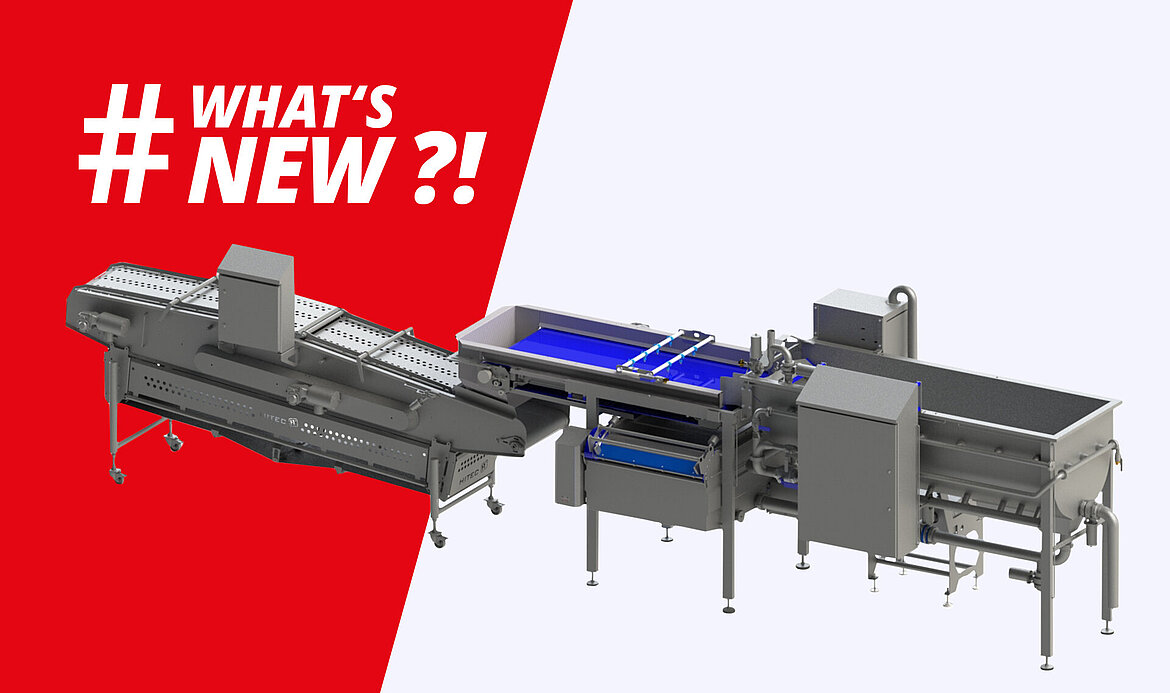

The seed quantity that needs to be processed is measured by a weighing screw and then transported to the GEWA 4000B-RT washing machine for further processing. Here, the sunflower seeds are thoroughly washed and soaked in warm water, with the dwell time set to allow them to swell. The seeds are then discharged onto a knocking belt with an integrated spray shower, which moves them on to the next stage of processing. The seeds can be used to make products such as spreads, vegan rissoles and patties.

The SMART line is fitted with a control system. This enables recipe management, in which specific settings such as the dwell time and other parameters can be defined and saved. Users simply select a predefined recipe to start the process. The recorded data can be evaluated for quality control and to optimize production processes.

KRONEN already offers a multitude of solutions for processing meat substitute products or products from plant-based sources of protein and works together with pioneers in the food processing industry to constantly (further) develop solutions for this growing market.