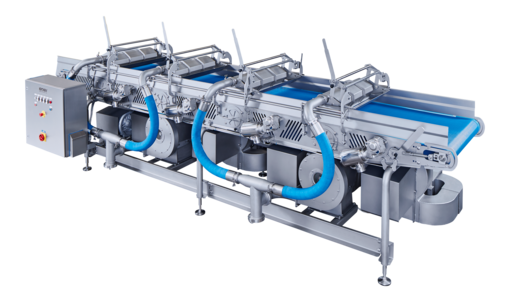

Dries lettuce, fruit and vegetables fully automatically, efficiently and hygienically: up to 2,800 kg of product per hour

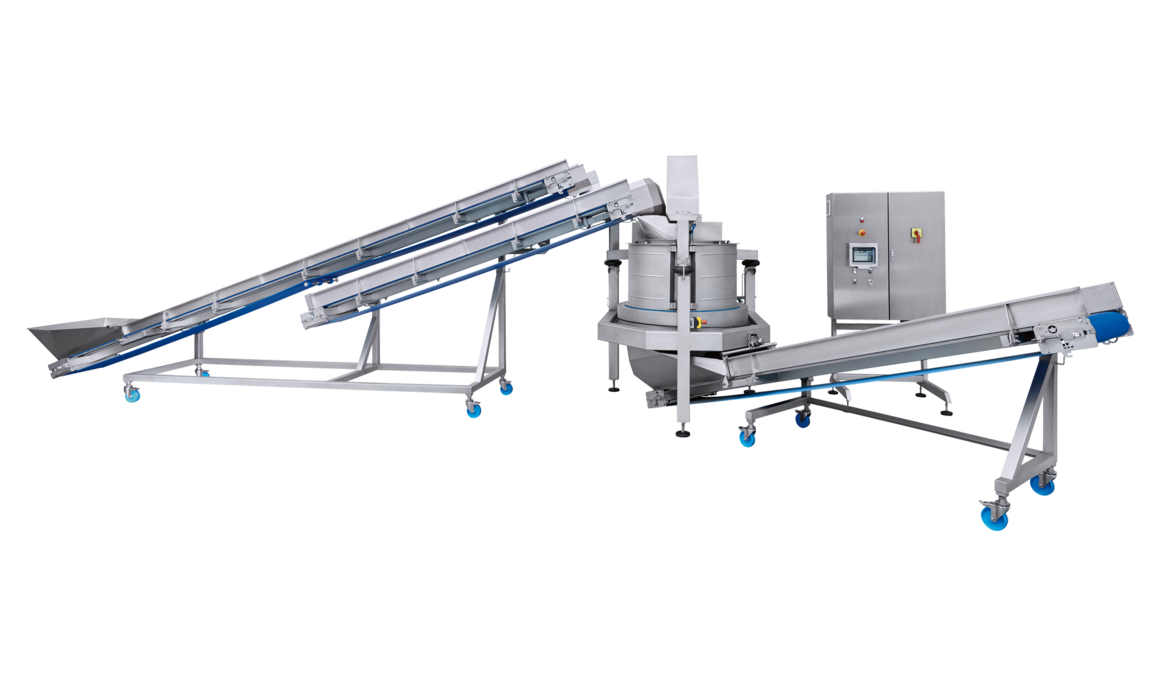

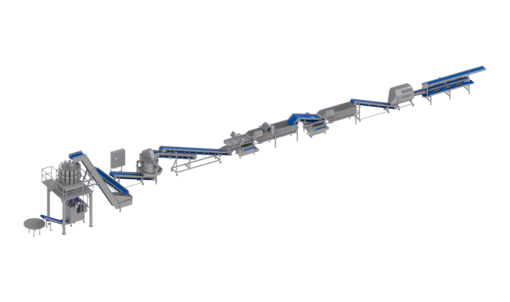

The K650 is a fully automatic drying system for lettuce, fruit and vegetables and is designed for operation in continuous processing lines.

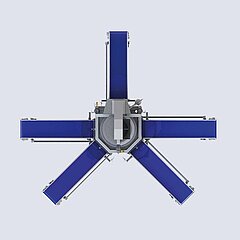

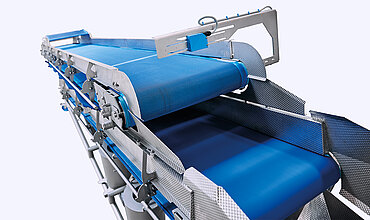

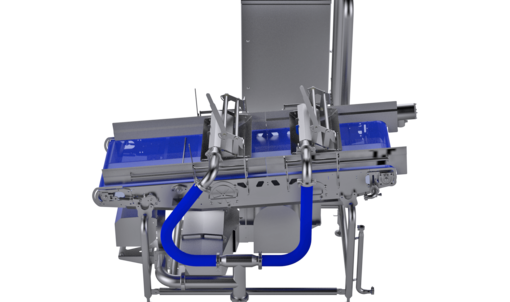

The product leaves the washing unit and is deposited on the infeed buffer conveyor. Due to the buffer conveyor, the K650 processes the product continuously, although the centrifuge itself dries in batches. As soon as the centrifuge with a 650 mm-diameter drum is full, the buffer conveyor runs in reverse mode until there is space in the centrifuge. With an optional volume control, the infed product quantity can be optimized. At the end of the drying cycle, the spinning speed is reduced and the product is gently forwarded to the discharge belt by a single blowing-off procedure. It is timed in such a way that the product flow is as even as possible. After drying, the product is transferred either into containers or onto the infeed belt of an automatic weighing or packaging machine. Without product, the unit automatically switches to energy-saving mode.

The K650 is supplied as a "Plug & Play" & version, meaning that only the cables of the individual components need to be connected in the switch cabinet to make the machine ready for operation. The switch cabinet is a free-standing unit and has a 10 m cable. The system is equipped with a TOSI-BOX for remote maintenance as standard. Optionally, the control unit can be upgraded with SMART functions.

For higher capacities up to 5,000 kg/h, the upgraded K850 drying system is suitable.