For cutting, washing, drying and packaging up to 2,000 kg per hour

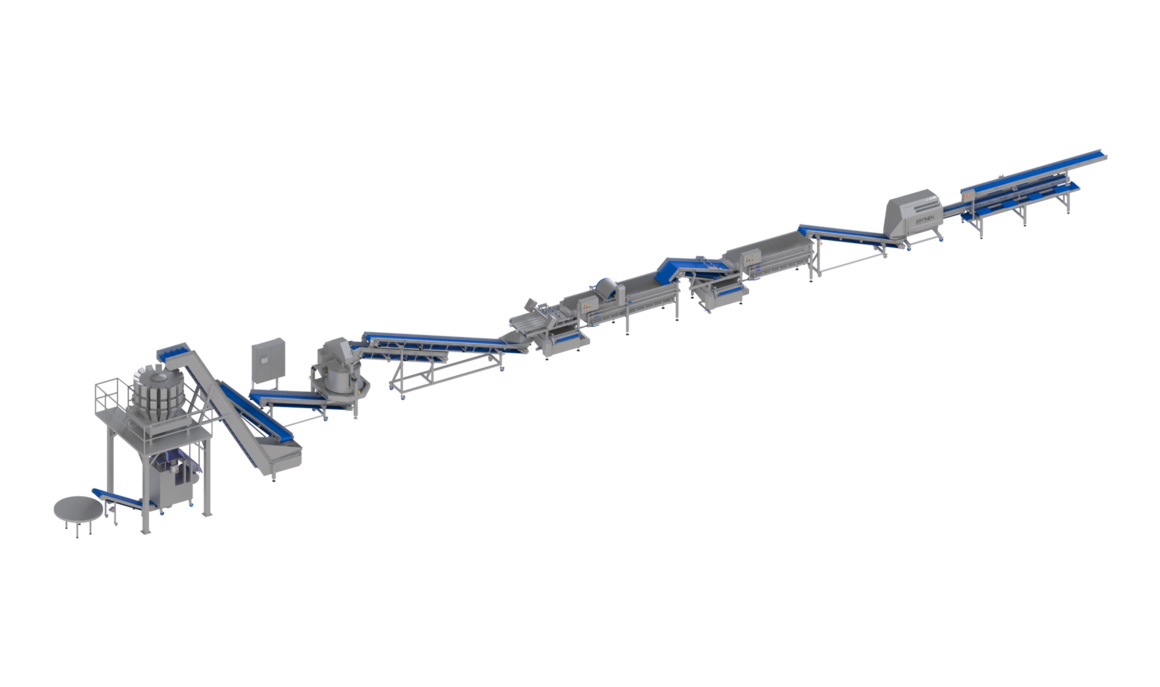

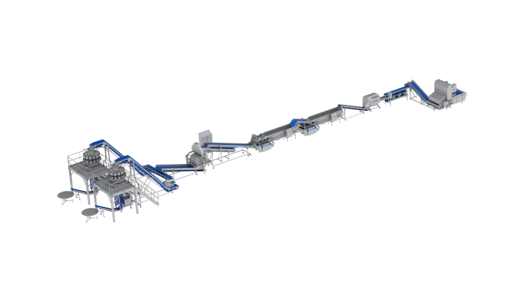

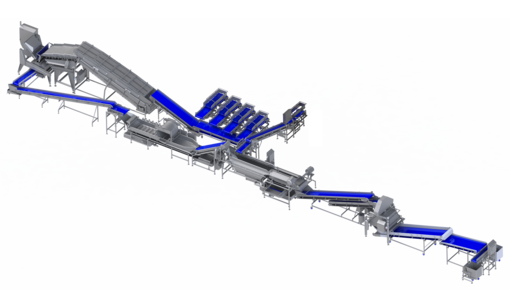

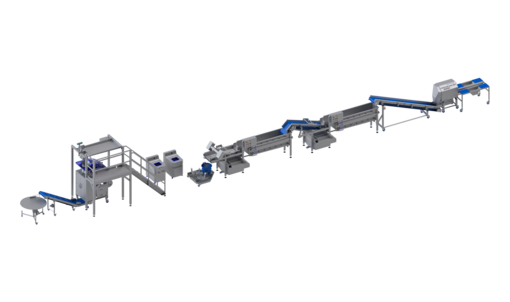

The semi-automatic lettuce processing and packaging line integrates several KRONEN machines with a solution from KRONEN's partner GKS Packaging. The line is used for the complete processing of the raw material to the end product packaged in bags.

The following machines or solutions are integrated:

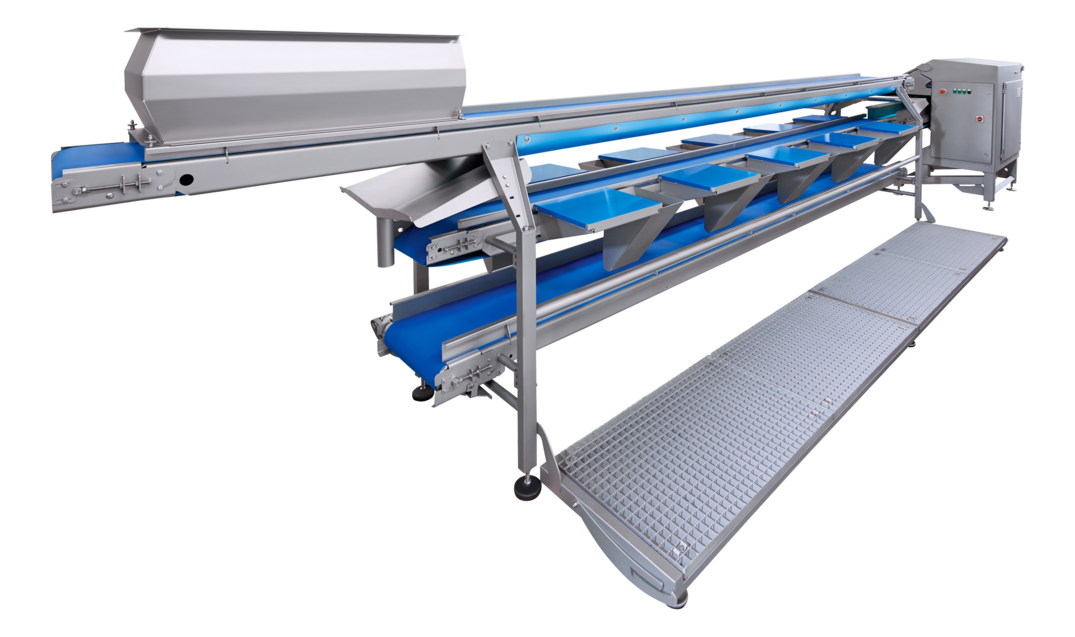

- Preparation: Trimming table for 8 people

- Cutting: GS 20 belt cutting machine , optionally with a wide range of knives

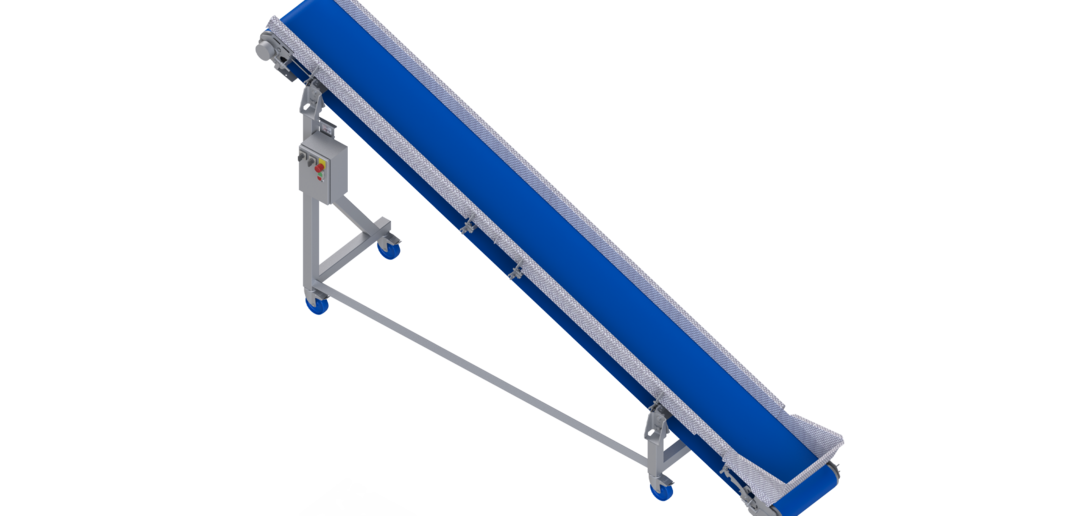

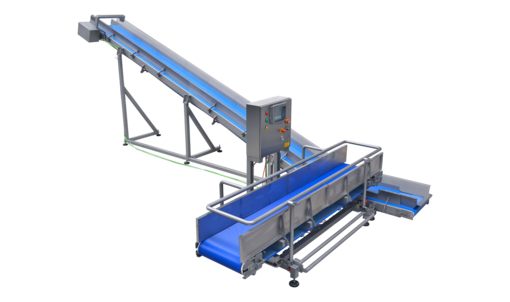

- Conveying: PLUS inclined conveyor belt

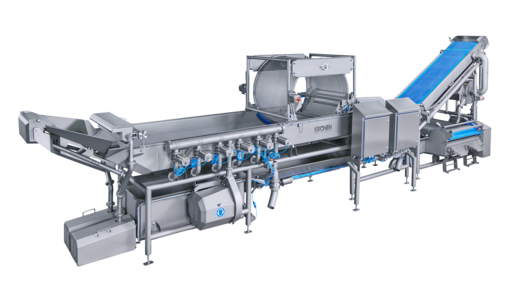

- Pre-washing: GEWA 4000 PLUS HELICAL washing machine with dipping belt outfeed

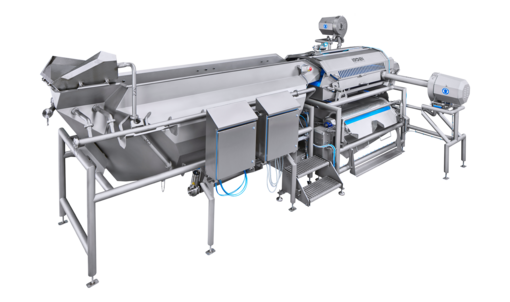

- Washing: GEWA 5000 PLUS HELICAL washing machine with vibration outfeed and an optional measuring and dosing system

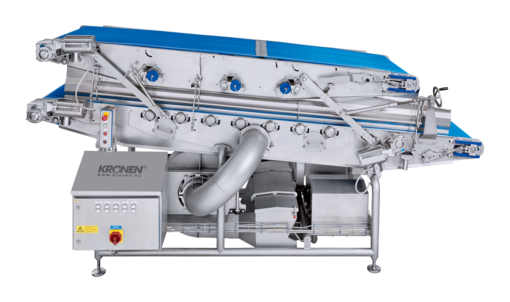

- Drying: K650 drying system

- Further transport: Shuttle belt with forward/reverse motion and 200 l standard trolley for buffering product

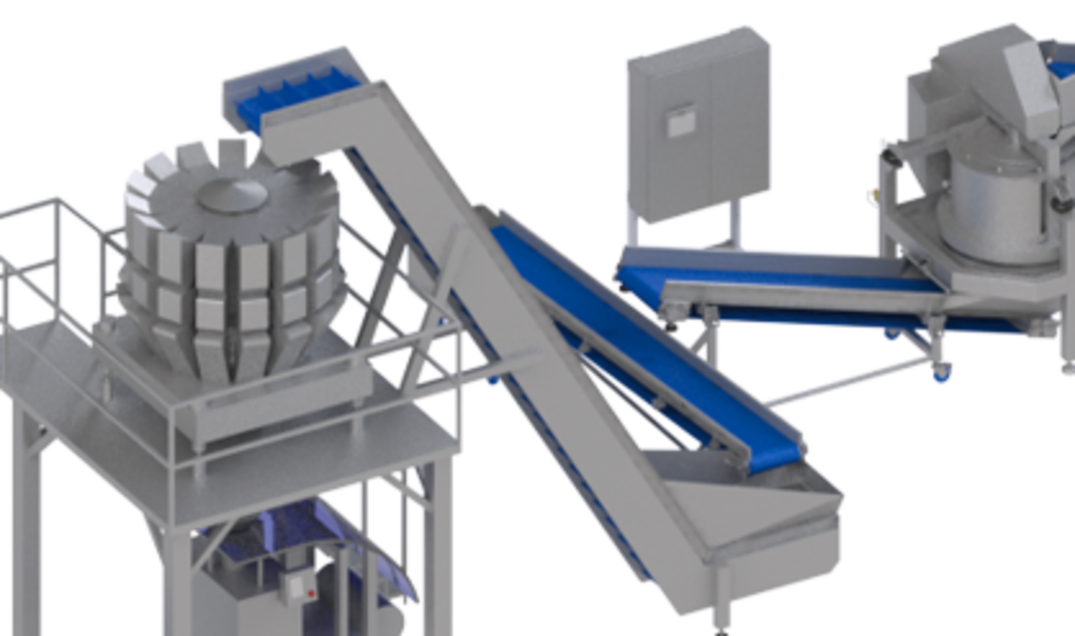

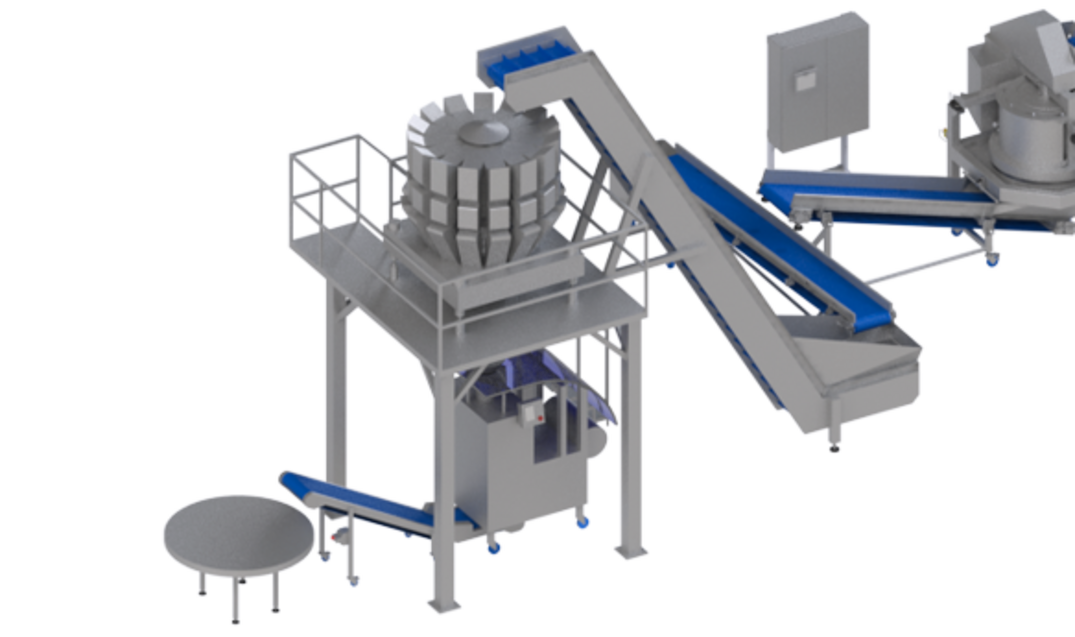

- Weighing and packaging: GKS Packaging solution with

- Slope conveyor

- Platform with multiple-head scales

- FLEX L packaging machine, the bags can be optionally treated via a connection for gas flushing (MAP) and also printed

- Outfeed belt, optionally with a metal detector

- Rotary table for buffering

If a second product is fed into the GEWA washing machine via a second cutting machine or a second belt, for example different types of lettuce, the products are mixed at the same time by the HELICAL washing system during the washing process.

Application options and capacities:

The system is used mainly for processing cut lettuce but also for cabbage and carrots as well as partially for whole lettuce leaves or other leafy products, for example mixed lettuce, arugula/rocket or baby leaf lettuce.

The capacity depends on the product and packaging size. For example, the line processes:

- up to 1,500 kg/h of iceberg lettuce

- up to 2,000 kg/h of cabbage and carrots (cut)

- up to 350–400 kg/h of arugula/rocket and baby leaf lettuce

The line is ideal for packaging bags with a width of up to 350 mm. A FLEX XL can be offered as an alternative instead of the FLEX L for packaging in bags with a width of up to 500 mm.

Please note: The video below shows an alternative processing line.