Since the beginning of 2023, the first HEWA 3800 washing machine has been reliably proving its worth in continuous operation at a fresh-cut production facility. A multitude of international clients have since received their HEWA washing machines and been impressed by their design, which has been optimized in terms of hygiene and further improves production efficiency and food safety as a result.

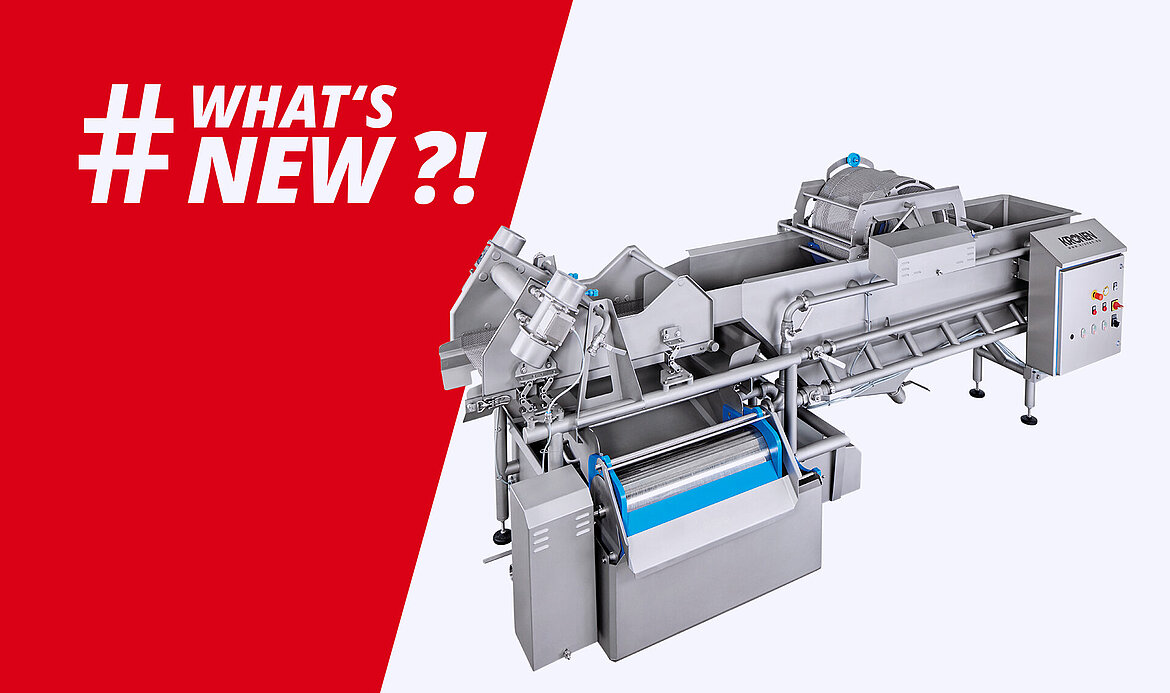

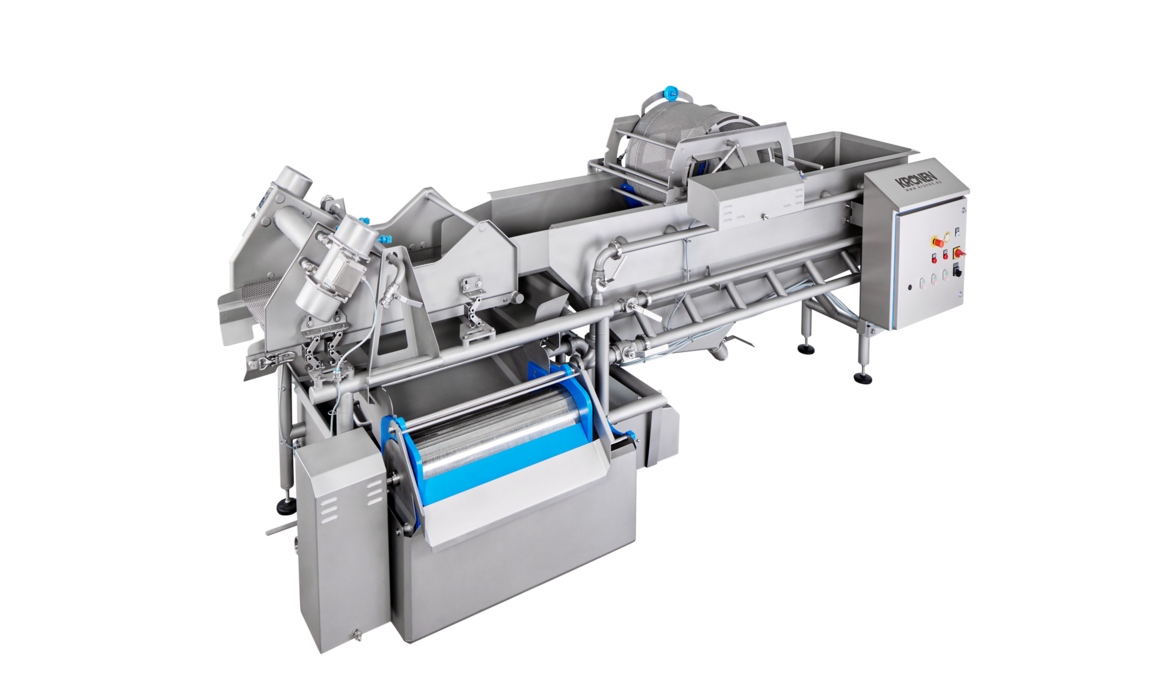

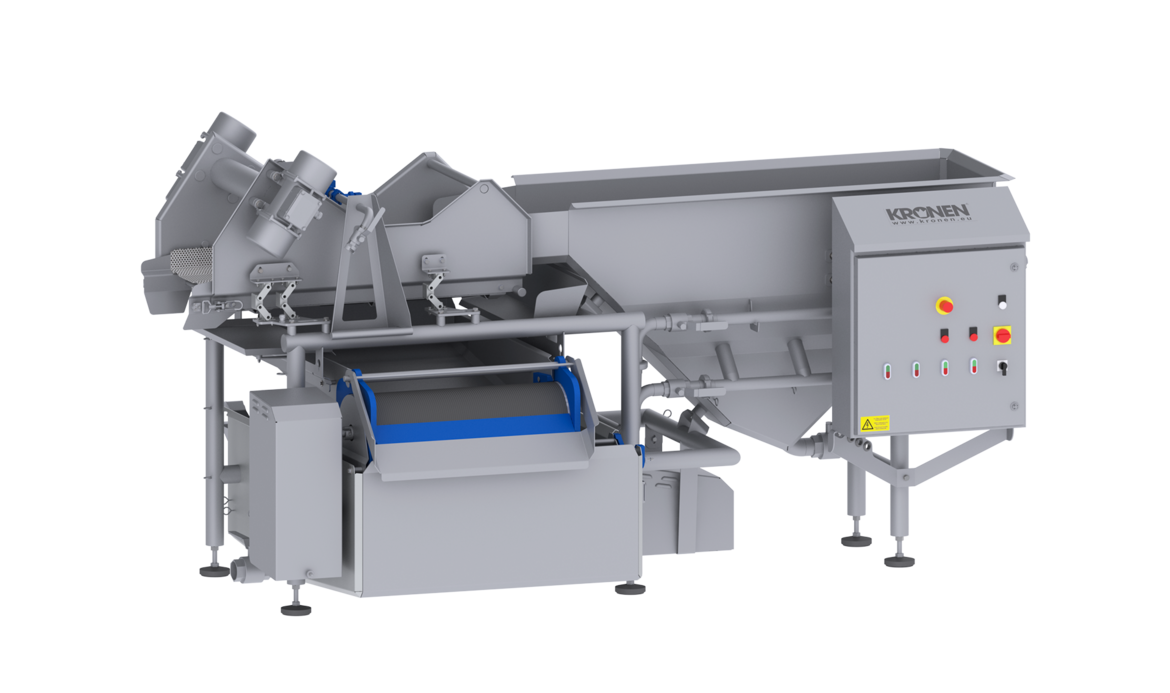

The HEWA 3800 HELICAL washing machine was launched at the Fruit Logistica trade show last year. The upgrade of the GEWA 3800 washing machine has been optimized in terms of hygiene and meets the growing demands of food processing companies with regard to simple, efficient cleaning, so much so that the machine can be completely dismantled for rapid and thorough cleaning results. Its design concept ensures maximum hygiene, for example the fact that the machine has no horizontal surfaces whatsoever. What’s more, all edges are designed to avoid the formation of biofilm.

When it comes to purchase decisions in the food processing industry, which handles products such as salad leaves, vegetables, fruit, herbs and other foodstuffs, hygienic design plays a central role by enabling reduced cleaning times and thus more efficient production, as well as saving staff costs, water and cleaning agents. Machines that are easier to clean also lead to an increase in product safety because the excellent accessibility of all parts of the machine reduces the risk of deposits that lead to the contamination of the food processed.

The growing importance of hygienic design among food processing machines is also reflected in the corresponding standards. As a member of the European Hygienic Engineering & Design Group (EHEDG) and via its exchanges with groups of experts and research establishments, the KRONEN team continuously works to expand its findings in the field of technology and hygienic design and to apply this new knowledge in its development activities.

After successful completion of its test phase in a development project, the first HEWA 3800 washing machine remained in the production facility of KRONEN’s project partner, a fresh-cut company in Germany, and now continues to reliably wash its baby leaf lettuce with perfect washing results. Over the past few months, a multitude of customers from various companies have already decided to make the most of KRONEN’s new generation of washing machines. The new washing machine owners can now benefit from the safest possible hygienic processing and time savings when cleaning their machines.

The HEWA 3800 and HEWA 2600 models have a processing capacity of up to 2,500 kg or 600 kg per hour and are used for the continuous pre-washing, washing, disinfection, mixing, treatment and rinsing of salad leaves, fruit and vegetables.