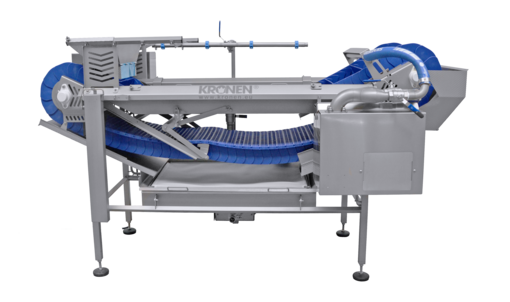

Process apples easily and quickly: semi-automatically peel, core and divide them into segments

The AS 2 peeling, slicing and coring machine for apples is a very compact, easy-to-use multifunctional tabletop device used in the high-care area of fruit processing. It is loaded manually, and up to three apples can be processed at the same time, meaning that up to 600 apples, equivalent to approximately 90 kg (at 150 g/apple), can be processed per hour. If additional apple slices are to be cut, the AS 4 or the AS 6 is a good option.

Processing in four steps:

- The apples are placed on the three product spikes by hand.

- The apples are peeled if necessary.

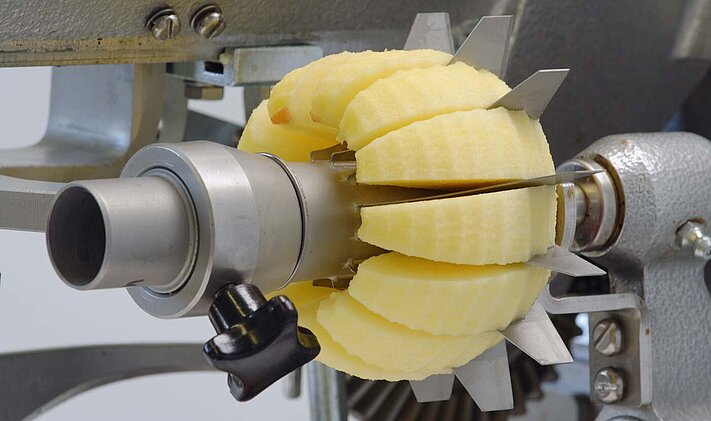

- The core is removed and segments are cut in the same step if required.

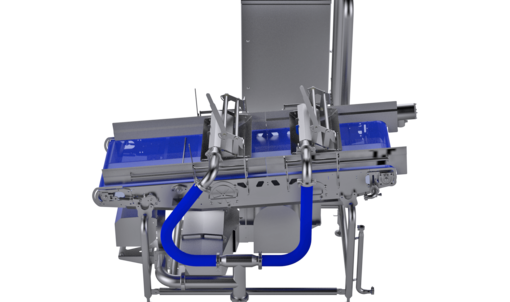

- The separating cylinder separates the finished product from the peel. With an optional separation system, the good product and waste (core and peel) are discharged into separate hoods.

Common uses:

- Fresh apple segments for fresh-cut snacks, peeled or unpeeled

- Peeled apple segments for a wide variety of applications in the field of bakery and confectionery products, such as chocolate-coated apples, cake toppings and fruit salad

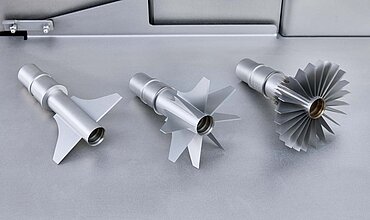

The machine processes whole apples with a diameter of 55 to 85 mm and a maximum height of 80 mm. As standard, the AS 2 comes with a cutting tube with a diameter of 20 mm with a scraper, a cutter head with a peeling knife, and a separating cylinder. In addition, a wide range of wedging knives and cutting tubes are optionally available.