Maximum waste reduction and perfect quality: slice, segment or dice up to 600 kg per hour

The GS 10-2 TTS is used for slicing and dicing an extremely wide variety of food products. Thanks to the sensor technology and PLC control, slices, cubes or segments can be cut almost without waste. Depending on the product and cutting type, the GS 10-2 TTS processes up to 600 kg of product per hour.

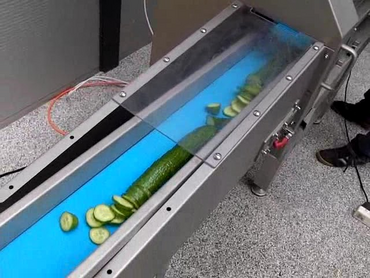

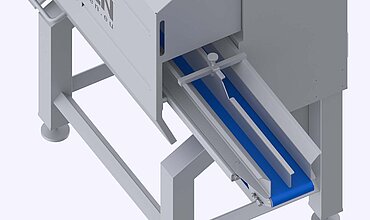

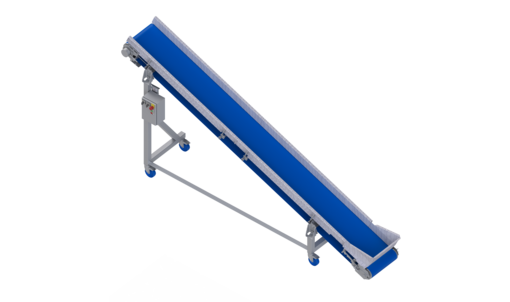

The functional layout is identical to that of the GS10-2 but in addition, the TTS version has an extended infeed belt to which a trimming station can be added, as well as a screen on which the exact processing parameters are set. The knife is controlled by a servo motor and only begins to rotate when the product arrives at the end of the infeed belt and is ready for the first cut to be made. The GS10-2 TTS calculates the length of the product and the necessary number of cuts required to cut the exact number of slices or segments in the desired cutting thickness. This results in the maximum possible yield of good product from the raw product, with almost no waste. The TTS function can also be used to cut off the ends of a product (top and tail function), for example carrots or cucumbers, so that only the good product is processed into uniform slices or segments as desired. The optional discharge belt is recommended for removal.

Versatile application options

The TTS version of the GS 10-2 is suitable for various applications, for example:

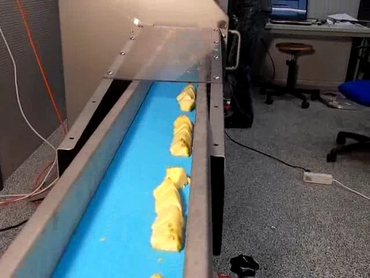

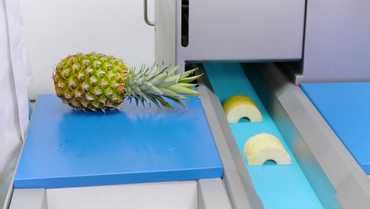

- Segmenting or dicing pineapples and melons

- Cutting (top and tail) and slicing carrots, cucumbers and baguettes

- Cutting cabanossi or bockwurst sausage into slices

- Cutting vegan meat substitutes

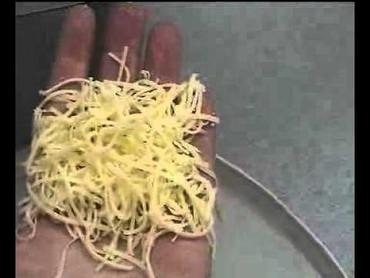

The machine can also be used as a normal GS 10-2 without the TTS function. It will then cut, slice, grate, rasp or dice almost any type of food product, including lettuce, leafy product,s herbs, meat, fish, baked goods, cheese and nuts.

Note: The videos show the GS 10-2 without the TTS function.