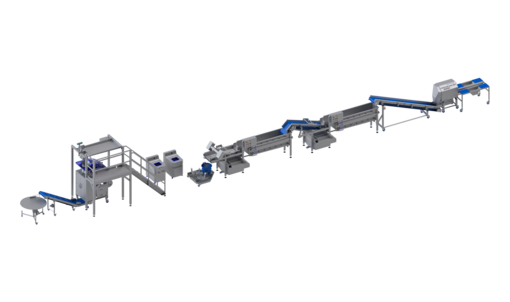

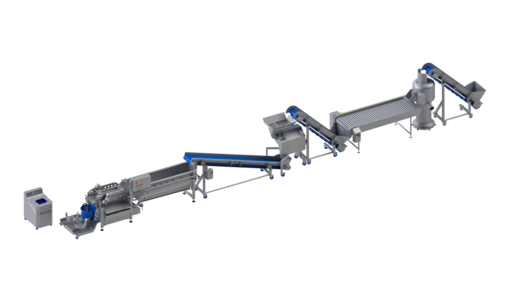

For peeling, cutting, washing and drying products – up to 400 kg/h

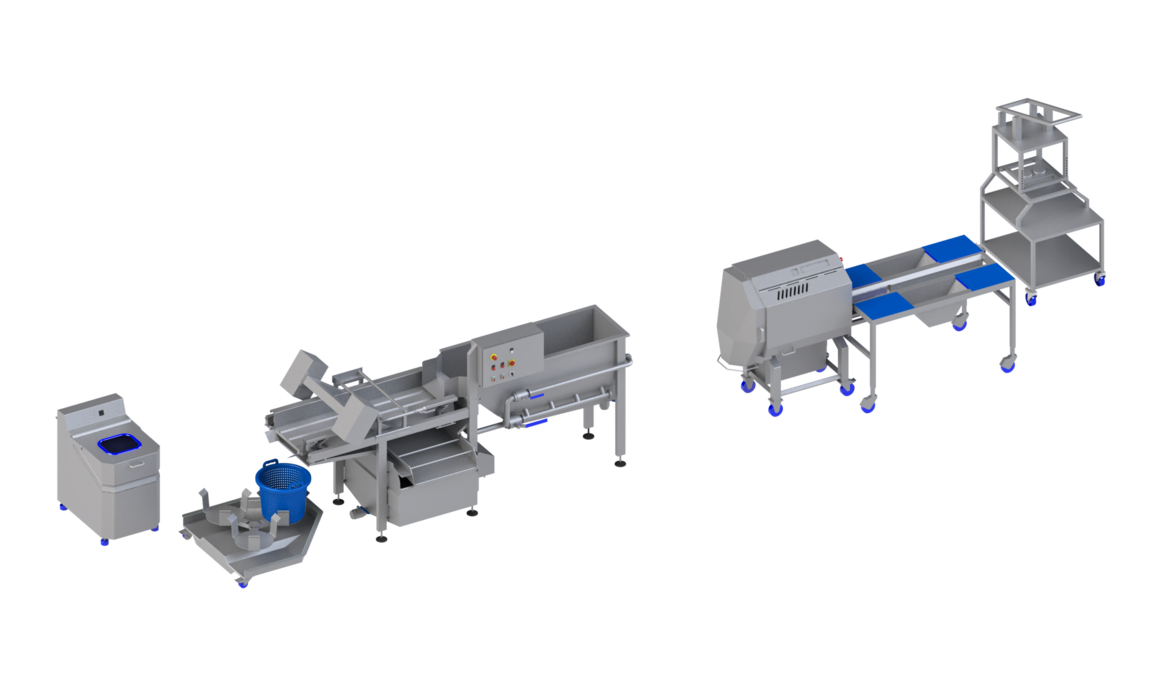

In the semi-automatic processing line, the product is first pre-trimmed, cored or otherwise prepared. It is subsequently placed onto the belt of the cutting machine, where it is cut and then falls into a collecting container. An employee pours the product into the washing machine, where it is washed or treated. After the washing process, it is placed into spin baskets situated on a basket carousel. Another employee places the filled baskets into the spinners one after the other. The product can then be further processed.

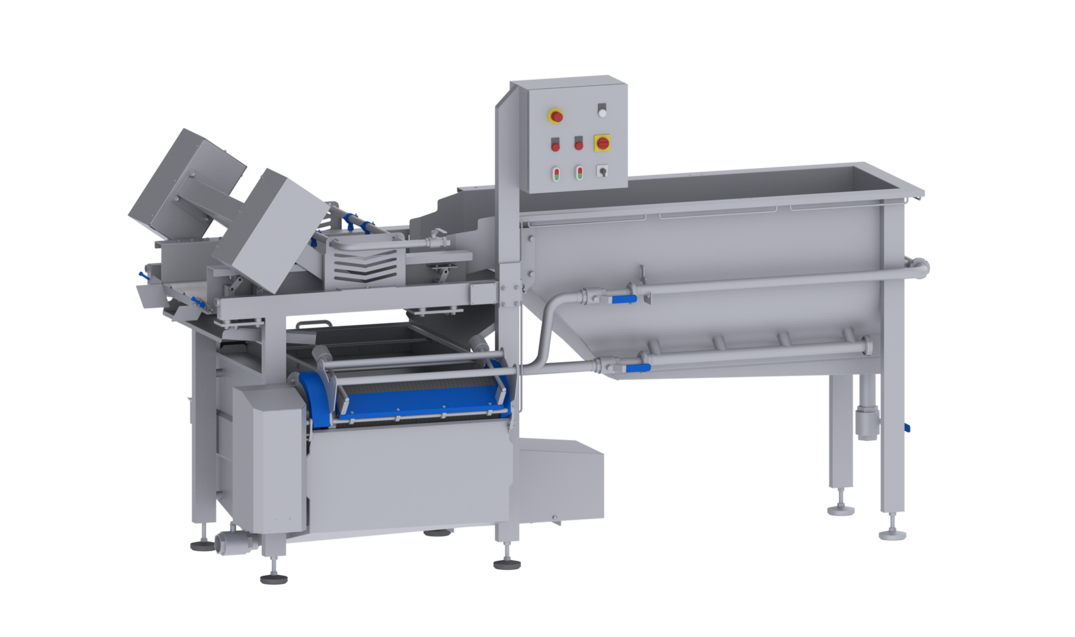

Professional preparation at the trimming table, precise and continuous cutting with the GS 10-2 and effective yet gentle washing and spinning produce excellent end results. Cleaning the line is particularly easy as no conveyor belts are used.

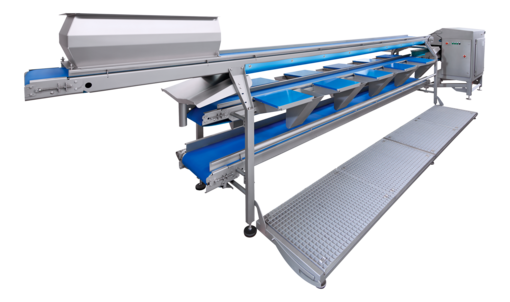

The following machines or solutions are integrated:

- Preparation: Trimming table for 4 people and HGW manual grid cutter with base frame

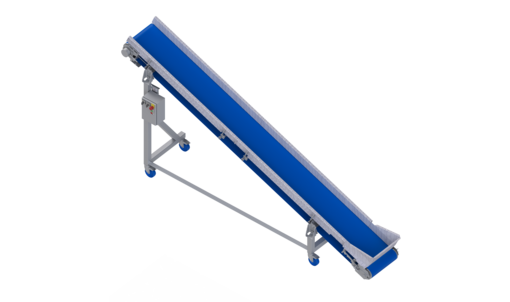

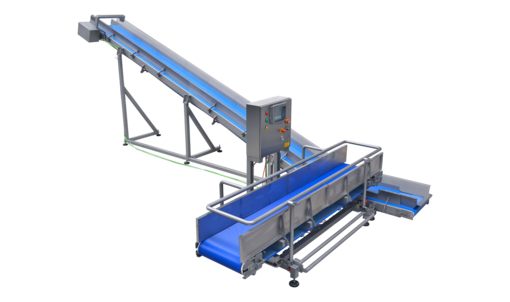

- Cutting: GS10-2 belt cutting machine, optionally with an outfeed belt and a wide range of various knives

- Washing: GEWA 2600 PLUS HELICAL washing machine with vibration outfeed and an optional measuring and dosing system or UVC water reactor

- Drying: KS-100 PLUS with a basket carousel

Application options and capacities:

The system is suitable for processing lettuce, vegetables, fruit and vegan products. The line is often used for products that are processed with the GS 10-2 and require washing, for example cut lettuce, cut cabbage or cut carrots.

The capacity depends on the product. For example, the line processes:

- up to 300 kg/h of iceberg lettuce

- up to 400 kg/h of cabbage

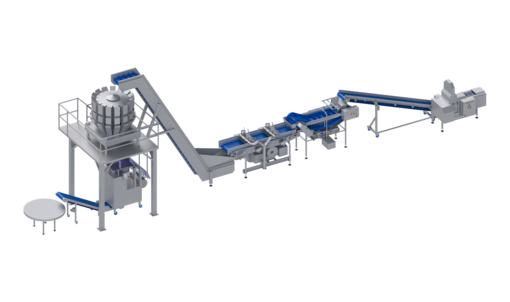

Please note: The video below shows an alternative processing line.