Business Report 2023: A medium-sized company sets the course for the future

In the previous business year, the family-run food technology manufacturer KRONEN recorded revenue of EUR 19.8 million and thus remained stable at a consistently high level. The company, which was taken over by Rudolf Hans Zillgith 25 years ago.

In the previous business year, the family-run food technology manufacturer KRONEN recorded revenue of EUR 19.8 million and thus remained stable at a consistently high level. The company, which was taken over by Rudolf Hans Zillgith 25 years ago, is active and successful with sales in 120 countries worldwide. Its Customer Day 2023, an in-house exhibition held in Kehl-Goldscheuer, Germany, welcomed around 180 interested visitors from locations all over the globe. In addition to such successful events, KRONEN is also continuing to invest in innovation, research and a staff-oriented corporate culture, as well as honoring its long-standing employees and focusing on providing vocational training in-house. Last year, its apprentice Tim Kehret was even awarded the title of Best Metal Engineering Apprentice in the German state of Baden-Wuerttemberg.

The global framework conditions that have led to strong increases in costs since 2022 and made developments uncertain in several regions continue to pose a challenge to all companies in the present day. Nonetheless, the company KRONEN GmbH, based in Kehl-Goldscheuer, Germany, has been able to achieve stable revenue at the same high level as the previous year.

”We benefit from a strong sales network in around 80 countries and from our excellent global reputation thanks to the high quality of our machines and systems and the fact that we offer our customers made-to-measure solutions for their applications. To achieve this, we invest intensively in research and innovation,” states Stephan Zillgith, Managing Director of KRONEN. “Our team-oriented corporate culture, which always focuses on our employees, plays a key role in our success. Our order balance is continuing to develop extremely positively, thus allowing us to also look forward to this business year with an optimistic mindset.”

International projects: washing lettuce in France, drying pineapple in Uganda or processing vegetables in Belgium

International exports make up a significant amount of the company’s revenue, with KRONEN GmbH supplying its solutions for processing lettuce, fruit, vegetables and other foods to 120 countries. International trade shows therefore play an important role, above all KRONEN’s own Customer Day, which took place again in 2023. 180 participants from all over the globe visited the company’s in-house exhibition in Kehl am Rhein on September 28 and 29 last year.

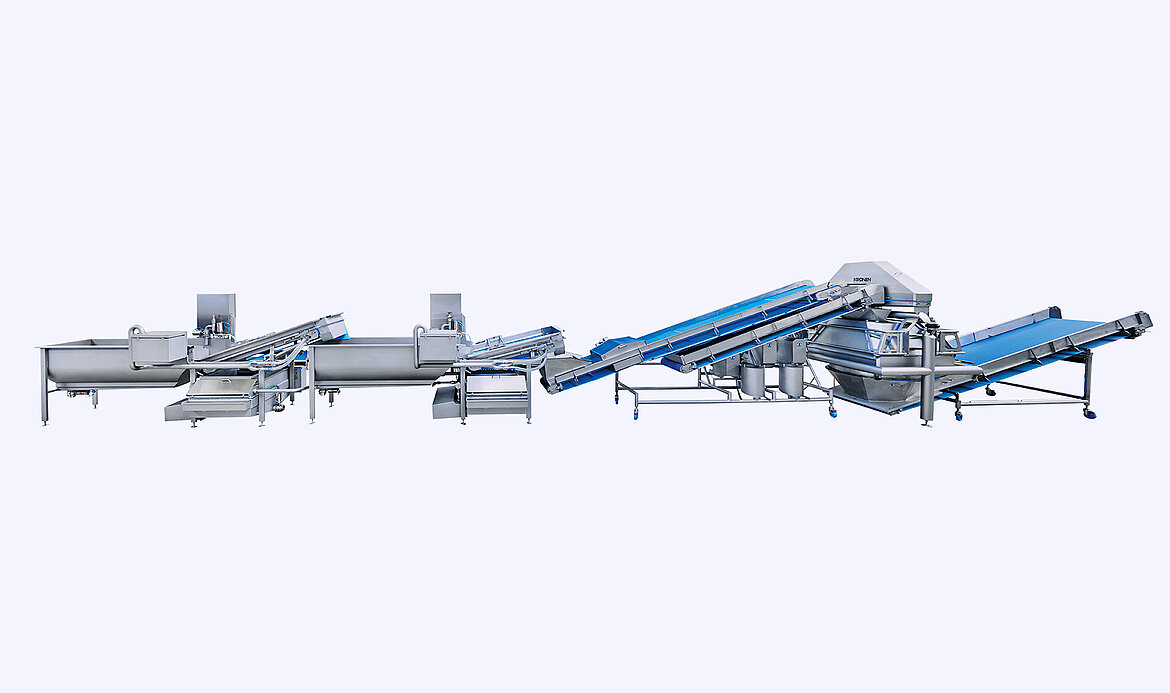

In 2023, KRONEN yet again sold a multitude of machines and systems to customers throughout the world and put them into operation in their destinations. In October, for example, KRONEN delivered a processing line for lettuce and vegetables to a customer in Belgium. This line can be used to process products such as up to 2500 kg of iceberg lettuce or up to 600 kg of rocket per hour. When handling products such as onions or carrot sticks, the system can process a maximum of 4000 kg per hour.

Last spring, the company installed a new line for washing lettuce for the French family company Voie Verte, which is located near Lyon and cultivates its own produce. In addition to selling its products to regional and national supermarkets such as Leclerc, System U and Intermarché, Voie Verte also supplies catering establishments with raw produce and ready-to-eat cut and washed salad and vegetable products.

In the previous business year, a charity project took KRONEN all the way to Africa. With the aim of providing a smallholders’ cooperative in the Ugandan sub-county of Kangulumira with future prospects, a fair income and a sustainable increase in prosperity, the Austrian company Twiga Sun Fruits GmbH launched a project for the production of solar-dried pineapple: organic, fair and meeting European quality standards. In 2023, KRONEN donated the machines needed to peel, core and cut the pineapples.

Innovation and research: Hygienic and sustainable lettuce, fruit and vegetable processing

Last year, KRONEN was granted a patent for its GEWA 3850V PLUS washing machine for sorting, cleaning and washing 1200 kg of bell peppers in Germany. The machine processes the complete cut pepper, including the stem, core and seeds. In one single step, a unique, clever system uses different water flows to separate the good product from the waste during the washing process. This eliminates the additional time-consuming stages of cleaning and sorting.

In the previous business year, KRONEN also celebrated the official conclusion of its research project SPLASH. The project, which was funded by the German Federal Ministry of Food and Agriculture (BMEL) aimed to prevent the risk of packaged cut salads being contaminated with microorganisms. The project team developed an innovative washing process for freshly cut lettuce in plasma-treated wash water, which gently disinfects the products in a resource-conserving procedure.

KRONEN GmbH launches new solutions on the market every year, and 2023 was no exception, welcoming products such as the KUJ-HC 220 cube, strip & slice cutting machine, which can cut up to 8000 kg of fruit, vegetables and other foods and has been optimized in terms of maximum hygiene. When it comes to processing foods, optimal hygiene is a prerequisite. Of course, this also applies to the machines used to process food products.

Further development in Goldscheuer and Achern

Over the past five years, KRONEN has also made significant progress when it comes to manufacturing knives and blades for its own cutting machines. The company invests in modern machines and test equipment to produce the best blades to meet its customers’ needs. As a result, KRONEN is currently in a better position than ever before, despite the challenges faced in the procurement market. After all, it has not only optimized its own production activities but also established strong partnerships with knife and blade suppliers.

”In addition to strengthening our production facilities in Goldscheuer and Achern and our supply chains, we are also consistently focusing on driving digitalization within our company,” declares Stephan Zillgith. “We are already performing at a very high level, which allows us to immediately achieve competitive advantages in the present day. In the future, this approach will play a decisive role in determining our success.”

Honoring long-standing employees and an apprentice

“We are well aware of the importance of a good team. This is why we strive to create a corporate culture in which our employees are satisfied and can draw on their individual strengths. The willingness to work together to improve and develop further plays an essential role and is a key factor behind our success. This approach will continue to determine our course in the future,“ states Stephan Zillgith.

At KRONEN’s Christmas party, the Management Board thanked its long-standing employees and congratulated them on the anniversaries of their time at the company.

- For 30 years at KRONEN: Karin Danner, Danièle Herlin

- For 25 years at KRONEN: Sergey Efimov

- For 20 years at KRONEN: Olga Maurer

- For 10 years at KRONEN: Jörg Blust, Detlef Albert Gruseck, Bernd Hollinger, Azizah Schmeiser, Philipp Wollenbär

KRONEN also congratulated its apprentice Tim Kehret on achieving the title of Best Metal Engineering Apprentice in the state of Baden-Wuerttemberg. He was presented with this special award together with other graduate apprentices at the graduation ceremony of the local Chamber of Industry and Commerce (IHK), held at the Europa-Park. One of the nearly 2,000 guests at the ceremony was KRONEN’s Managing Director Stephan Zillgith, who personally congratulated Tim Kehret on his award as the best in the state on stage.

Anniversary: 25 years of Zillgith & KRONEN

KRONEN was originally founded in 1978. In 1998, Rudolf Hans Zillgith transformed the former business division of machines for the salad, fruit and vegetable industry into an independent company and took the helm as the Managing Director of the new KRONEN GmbH. Under his management and with a strategy of further orientation toward exports, the company soon established itself in international markets and achieved impressive growth.

In celebration of this year’s company anniversary, Alwin Wagner, Deputy Managing Director of the Chamber of Industry and Commerce of the Southern Upper Rhine Area (IHK Südlicher Oberrhein), presented Rudolf Hans Zillgith with the IHK certificate of honor and congratulated him on his entrepreneurial foresight and achievements. Given that the senior manager had also recently celebrated his 80th birthday, the entire Management Board and KRONEN employees also shared their congratulations.

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product portfolio of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging.

KRONEN additionally offers machines for the processing of meat and fish, special vegan products, baked goods and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide and supplies its products to more than 120 nations all over the globe.

With more than 45 years of experience in food technology, KRONEN prides itself on its quality awareness and constantly strives to achieve the best possible solutions in its day-to-day work. The machine manufacturer focuses on taking a sustainable, holistic approach toward the hygienic, reliable and resource-friendly production of fresh foods. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.