At Fruit Logistica 2025, we will present a broad spectrum of machines for disinfecting, peeling, washing, cutting, drying and packing fresh products. These machines will represent a variety of capacities, with products ranging from handheld devices to machines able to process large capacities offering ideal solutions for all customer needs.

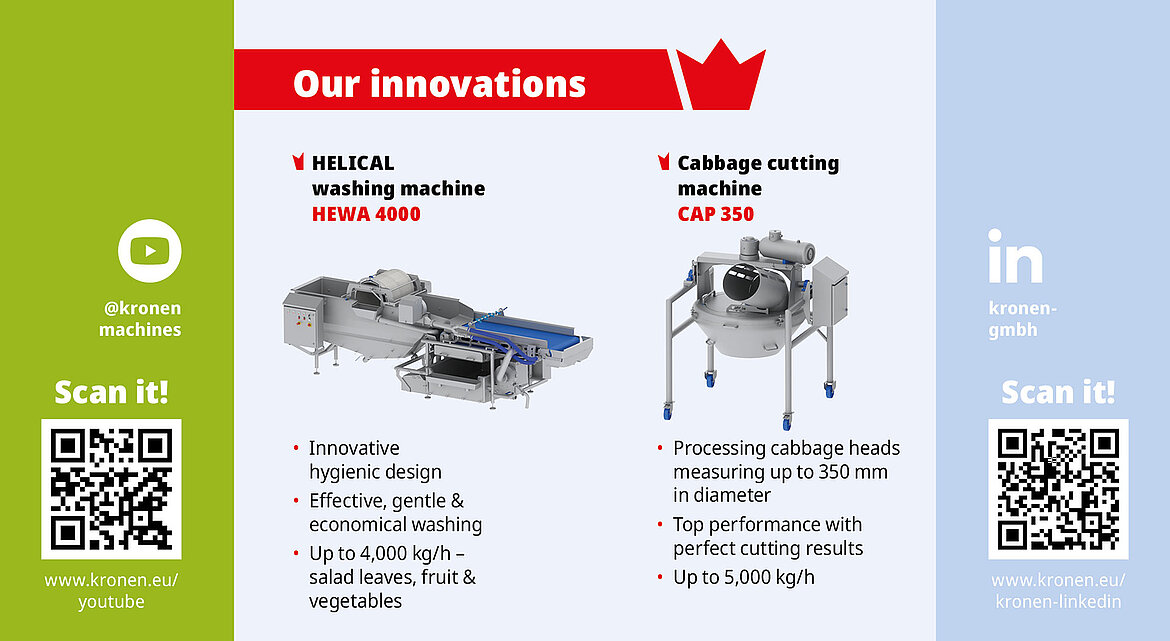

Efficiently processing large cabbage heads: the CAP 350 cabbage cutting machine

The cabbage cutting machine is an upgraded version of KRONEN’s CAP 68 model. The new CAP 350 version is able to cut even larger heads of cabbage and features an optimized hygienic design.

-

The CAP 350 can process 5,000 kg per hour: nearly twice the capacity of the CAP 68. When cutting cabbage into 1.3-mm-thick slices, for example, it can process up to 2,000 kg per hour depending on the size of the raw produce.

-

The cabbage cutting machine has also been optimized in terms of accessibility and hygiene. Its open design with removable covers enables easier cleaning and rapid cutting disk replacement.

High capacities and a hygienic design: the HEWA 4000 HELICAL washing machine

The HEWA 4000 HELICAL washing machine is an upgraded version of the GEWA 4000 PLUS. It has been optimized in terms of hygiene and a reduced cleaning time. Like the GEWA 4000 PLUS, the machine is used for the continuous pre-washing, washing, disinfection, mixing, treatment and rinsing of lettuce, fruit and vegetables. The HEWA 4000 can process up to 4,000 kg per hour.

The machine can be easily dismantled for rapid and thorough cleaning. Its design concept also ensures maximum hygiene, for example the fact that the machine has no horizontal surfaces whatsoever, thus allowing the water to optimally discharge. What’s more, all edges are designed to avoid the formation of biofilm. The vibration motors, all pipes, the pump casing, the wash and pump tanks and the covers and switch cabinet are made from AISI 304 stainless steel.

An optimized all-rounder: the HGW manual grid cutter

The HGW manual grid cutter has been used for fruit and vegetable processing all over the globe for many years. A multitude of cutting inserts are available for the machine, enabling it to be adapted to process various products and to cut, peel, punch and core fruit, vegetables and salad leaves.

The tabletop device has now been completely revised, and both its design and material have been optimized on several levels:

-

Processing larger products: The increased lift height now allows products with a height of up to 270 mm (using the dicing grid or segment divider) or up to 155 mm (using the pineapple cutter) to be processed.

-

Improved hygienic design: fewer drill holes and easier accessibility provide better hygiene.

-

Easier tool change: the cutting inserts are pre-assembled on a plate so that only the unit comprising the plate and the insert needs to be replaced.

-

Less effort required: manual operation requires less strength, and wear has been further reduced.

Visit us at Fruit Logistica: at stand A-20 in Hall 1.1!

You can find more information here