Dynamic weighing: Produces mixed products automatically, continuously and precisely

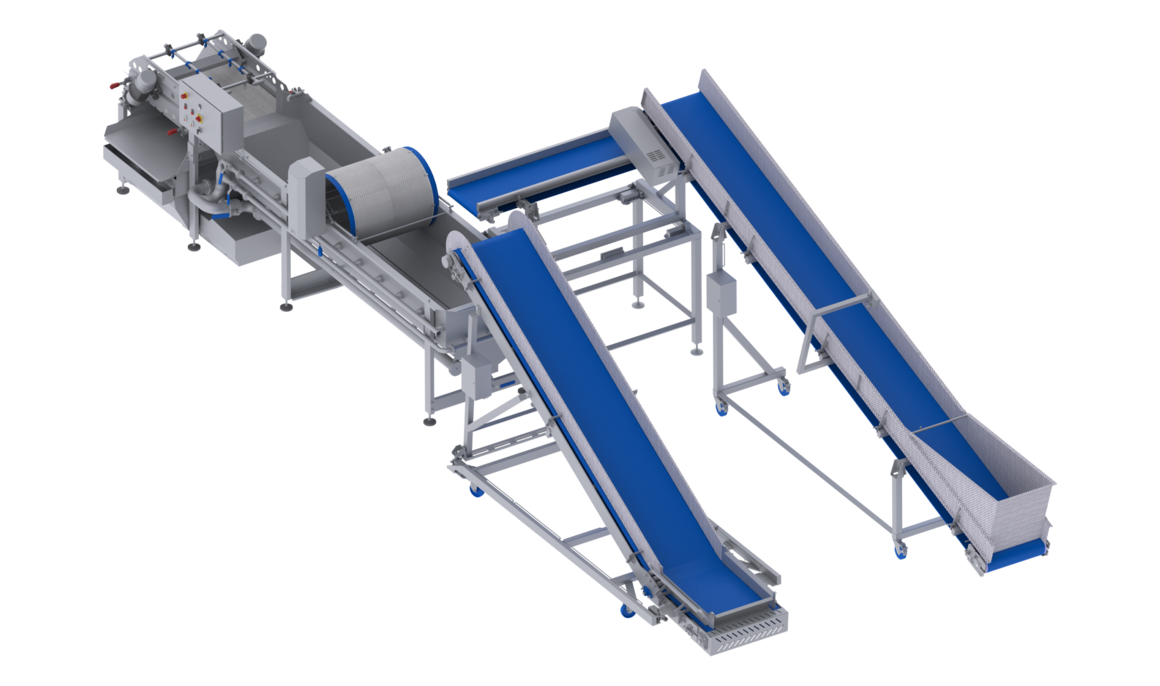

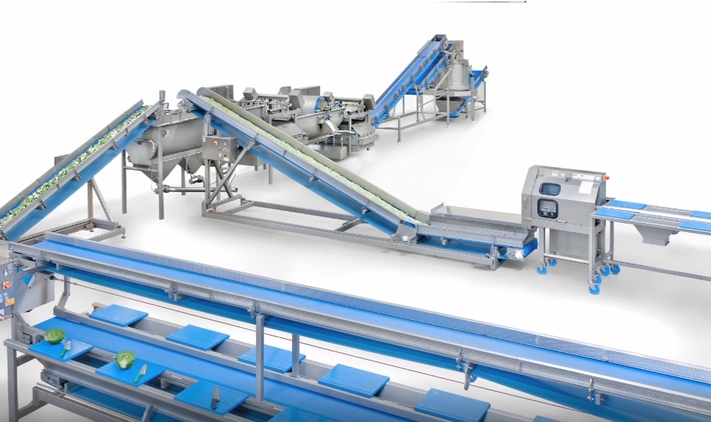

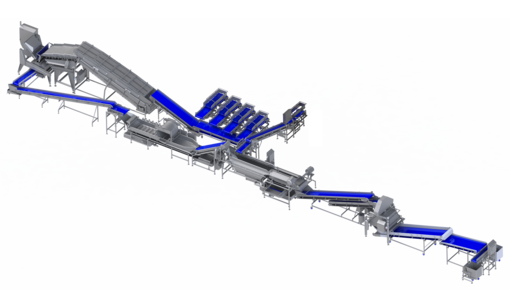

The automatic weighing belt system is a combination of weighing belts used to control and record the product flow through a processing line and to enable more precise mixing. The weighing belts are situated at the beginning of the line, in the area of the washing machines, and also particularly at the end of the line to record their output.

The system is available in a wide variety of models and can be adapted to individual requirements. Individual dynamic weighing belts can be used in processing lines to control and record the product flow. Combinations of several weighing belts are also possible to enable the controlled infeed of the raw material according to the recipes specified.

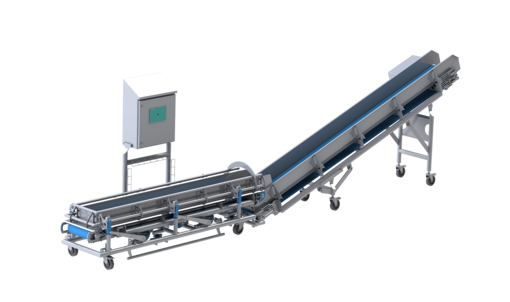

The simplest version of the weighing belt system is a static recipe weighing belt, which delivers the product mixture onto a dosing belt batch by batch, thus ensuring a continuous product flow into the processing line.

Versatile application options:

Weighing belts are used for both whole and cut products:

- All types of lettuce, salad products, vegetables and fruit

- Mixing of baby leaf salads, including pre-cut vegetable products (e.g. beetroot or carrot strips)

- Cut iceberg lettuce with carrot sticks and chopped cabbage

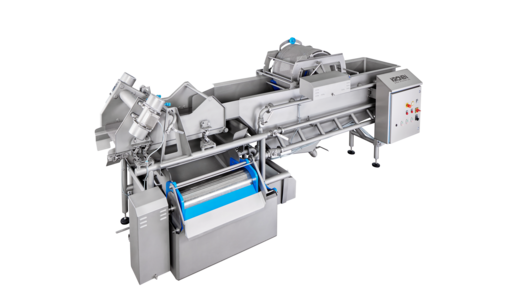

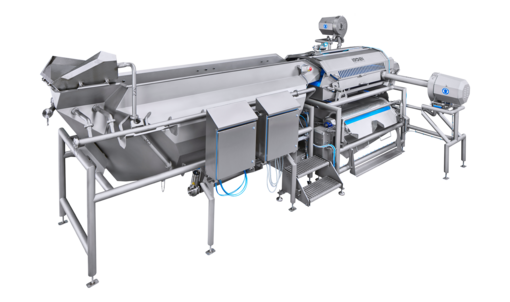

Weighing belts can also control the input in kg/h of cleaned lettuce into a cutting machine. A weighing belt installed downstream of the cutting machine can also record the product flow of the main component and add more components via other weighing belts, for example into the HELICAL washing machine, which is ideal for mixing.