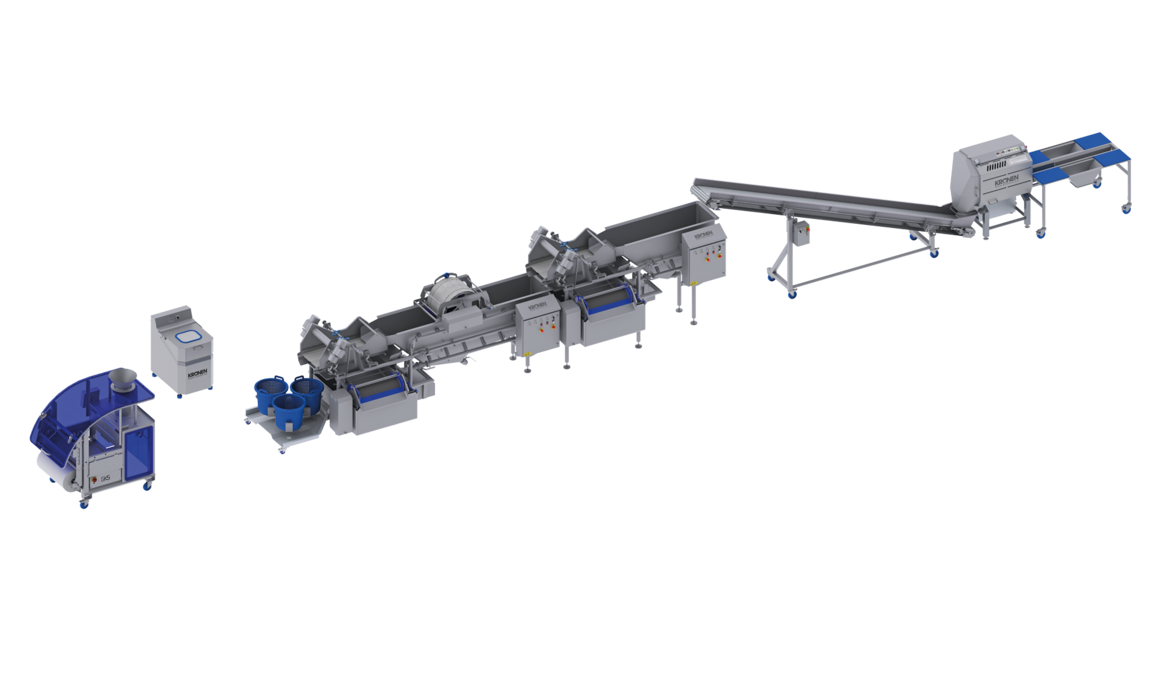

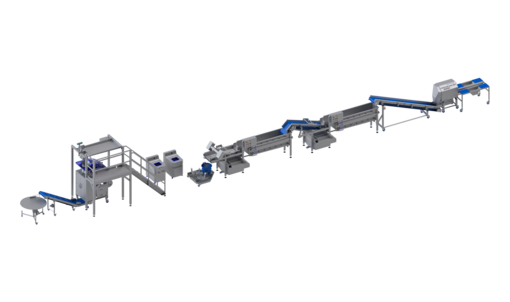

For cutting, washing, drying and packaging up to 600 kg of product per hour

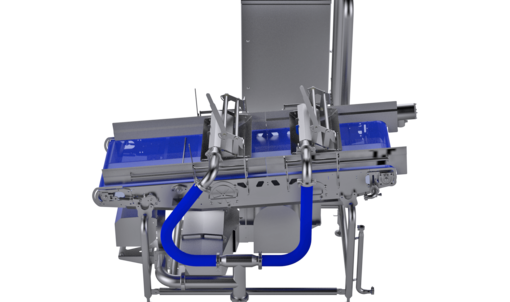

The semi-automatic processing and packaging line combines a multitude of KRONEN machines with a packaging solution from the KRONEN partner GKS Packaging. This setup is ideal for the start of line production activities and can be gradually extended with corresponding additions to expand production or to increase capacity gradually where needed.

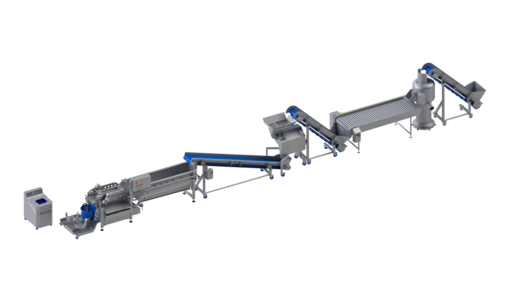

Professional preparation of food products at the trimming table, precise and continuous cutting with the GS 10-2 and gentle yet effective washing and spin-drying all produce outstanding end results.

The system is above all ideal for processing cut salad leaves but is also suitable for cabbage, carrots and other vegetables that require washing after being cut. The respective capacity depends on the product and the packaging size.

The following machines and solutions are integrated into the processing line:

- Preparation: Trimming table for 4 people

- Cutting: GS 10-2 belt cutting machine, optionally with an wide range of various knives

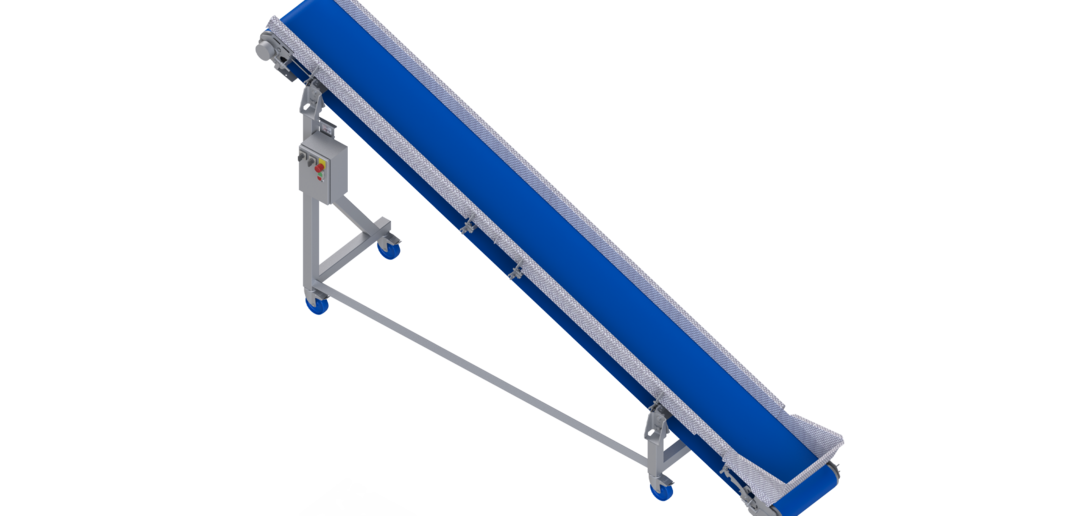

- Conveying: PLUS inclined conveyor belt

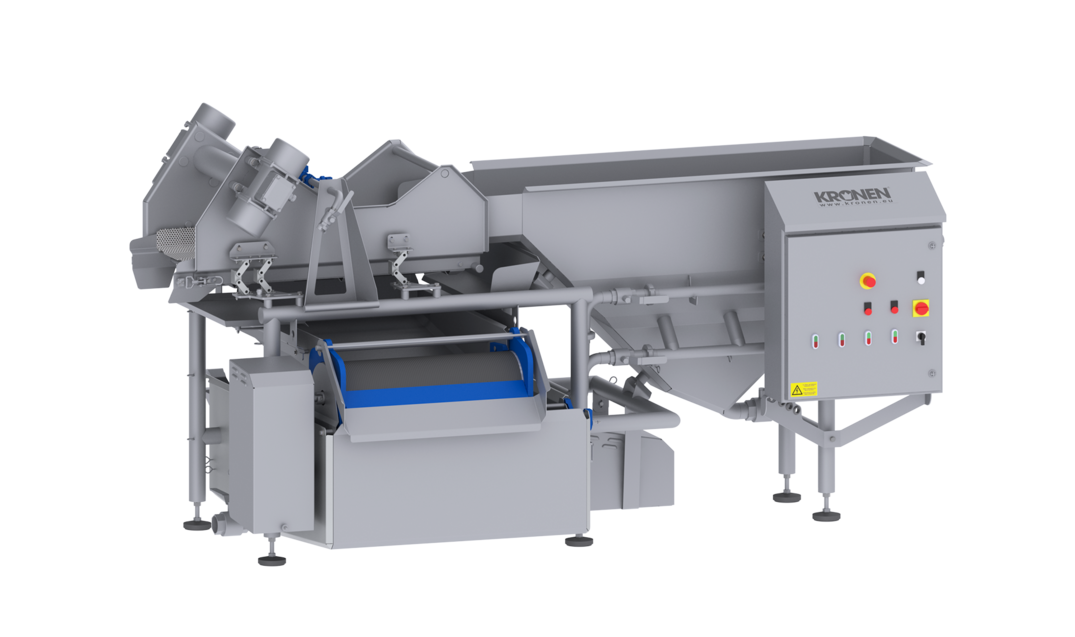

- Pre-washing: HEWA 2600 HELICAL washing machine with vibration outfeed

- Washing: HEWA 3800 HELICAL washing machine with vibration outfeed and an optional measuring and dosing system or UVC water reactor

- Drying: KS-100 PLUS lettuce and vegetable spin-dryers with a basket carousel

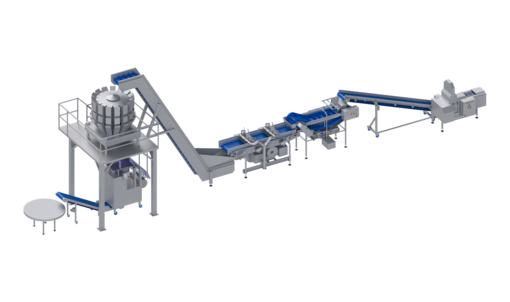

- Packaging: FLEX M GKS packaging machine , in which the bags can optionally be treated via a connection for gas flushing (MAP) and printed

After the washing process, the product is discharged into the spin baskets on a basket carousel. An operator then places the filled baskets in the spin-dryer one at a time. The line is ideal for packaging bags measuring up to 350 mm wide. Before packaging, the operator weighs out the right amount of the product manually.

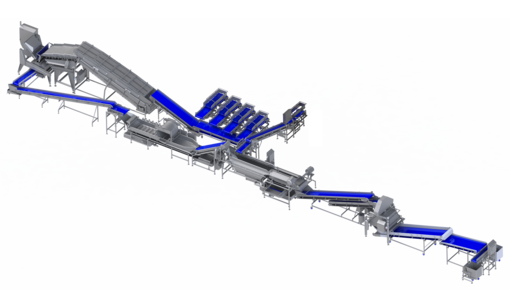

Flexible variations of or additions to the processing line:

- If a second product is fed into the HEWA washing machine via a second cutting machine or a second belt, for example different types of lettuce, the products are mixed simultaneously by the HELICAL washing system during the washing process.

- If necessary, the arrangement of the machines and the accessories can be changed in such a way that products that are to be washed first and then cut can also be processed.

- One or two additional centrifuges can be used to increase the capacity depending on the size of the packaging bags.

- The system can alternatively also be fitted with a semi-automatic or fully automatic weighing system.

Please note: The video below shows an alternative processing line.