Reliable UVC surface disinfection of food products as well as packaging materials and tools

The flow-through lock for UVC surface disinfection was developed in close cooperation with KRONEN's partner sterilAir®. The UVC Lock is a reliable and quick solution for reducing surface contamination during transfer to the hygiene area. Dry disinfection takes place without heat exposure and without undesirable additives or residues. The highly efficient UVC technology leads to excellent disinfection performance with a short contact time. This also results in the compact design of the machine and its practical use, even for heat-sensitive products.

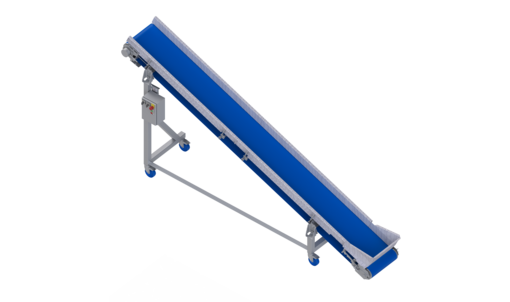

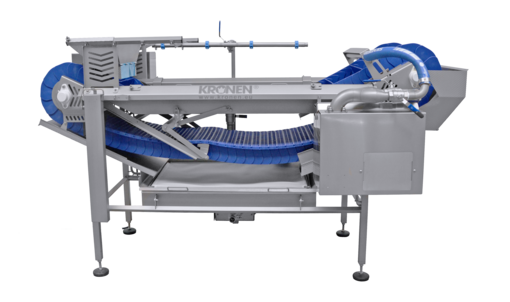

The products are brought onto the conveyor belt manually or in a processing line via the infeed belt and are guided through a screened area with UVC emitter tubes. The UVC Lock enables disinfection from all sides, while the efficient arrangement of the UVC emitters ensures a virtually complete radiation area. The stainless steel mesh conveyor belt ensures the minimum possible shading of the product from below. At the belt outfeed, the disinfected product is discharged, for example into the high-care area.

A wide range of application options:

The UVC Lock is frequently used for the surface disinfection of boxes, tools, packaging materials (e.g. buckets or cans), outer packaging of food products (e.g. sausages), and fruit and vegetable products before further processing, e.g. cabbages or pre-peeled onions and carrots.

The capacity depends on the product and the contact time, which determines the degree of germ reduction. Cabbages, for example, can be disinfected at a rate of up to 3,000 kg/h at belt speeds of 0.05 to 0.3 m/s. If transport boxes (600 x 400 mm) are used, this figure increases to up to 900 units per hour at a belt speed of 0.2 m/s.

Please note: The disinfection of food products depends on the country-specific statutory regulations.