Business Report 2024: KRONEN records constant growth and a new sales record

The medium-sized food technology manufacturer KRONEN GmbH has been achieving constant growth for many years. Last year, the company based in Kehl-Goldscheuer and Achern, Germany, honored yet more long-standing employees.

The medium-sized food technology manufacturer KRONEN GmbH has been achieving constant growth for many years. Despite challenging general conditions and a business environment with a number of economic difficulties, the family company was able to generate revenue of 21.0 million euros in the last business year, which represents revenue growth of 6% compared to the previous year. KRONEN GmbH is committed to internationality, innovation and a value-oriented corporate culture. Last year, the company based in Kehl-Goldscheuer and Achern, Germany, honored yet more long-standing employees and celebrated over 25 years of promoting and supporting in-house vocational training for young and upcoming talents.

“The fact that we have established our company on a global level and sell our machines and processing lines to customers in around 120 countries puts us in a good position to deal with times of crisis. What’s more, we supply our products to the food sector, especially the area of convenience food, which is and continues to be a growth market,” stated Stephan Zillgith, Managing Director of KRONEN. “This enables us to offer secure jobs. We plan to continue our successful growth over the years to come.”

KRONEN GmbH has a sales network in approximately 80 countries and continuously invests in the further and new development of tailor-made solutions for the fresh-cut and ready-made meal industries, as well as for large-scale catering and gastronomy companies, farm stores, manufacturers of vegan products, bakeries, butchers and pet food manufacturers.

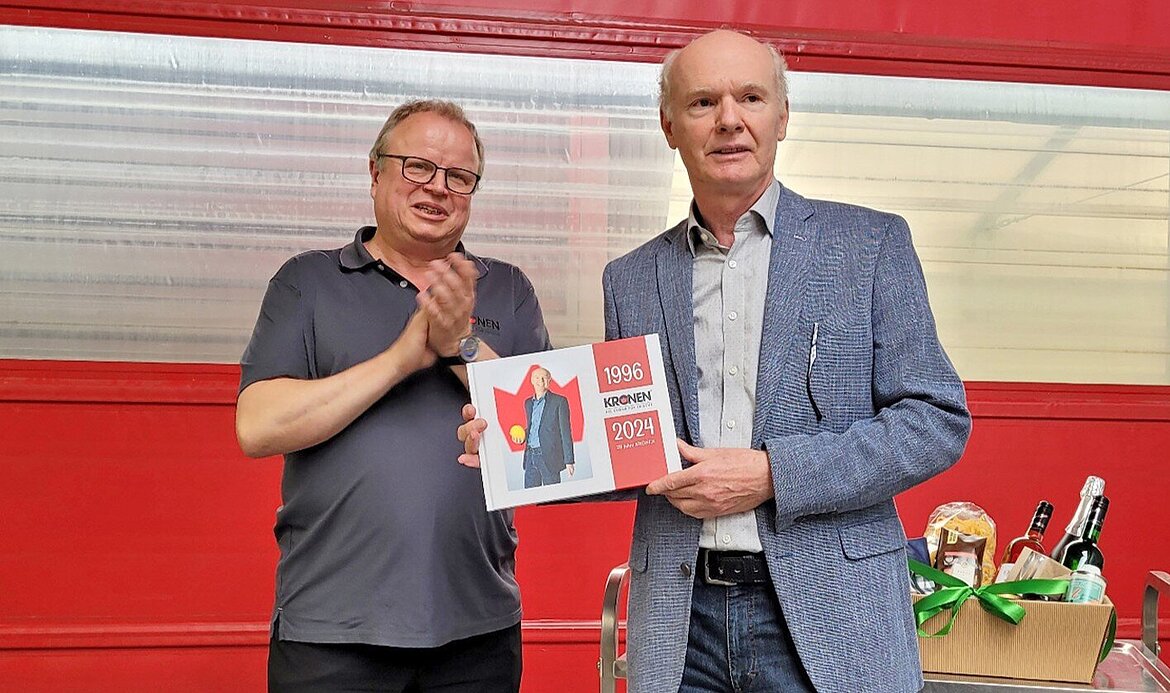

Honoring long-standing employees and a valued member of the Management Board

At the end of June 2024, Robert Lankhart, a highly valued member of the Management Board of KRONEN GmbH, bowed out into his well-earned retirement. “We would like to thank Robert Lankhart for his 28 years of dedicated work for our company and his significant contribution to its success,” declared Stephan Zillgith.

“We would also like to thank all of our long-standing employees. Teamwork and cooperation between our experienced employees and newer members of staff play an essential role in our corporate culture. We work together to develop and make constant progress, and this is one of the key factors behind our success.”

Last year, Stephan Zillgith himself, who has been working for KRONEN since 1999 and joined his father, Rudolf Hans Zillgith, as a Managing Director in 2010, was honored by the company for his work as a long-standing employee:

- 35 years at KRONEN: Maryline Cretin

- 30 years at KRONEN: Michael Matzek, Günther Wöhrle

- 25 years at KRONEN: Stephan Zillgith

- 20 years at KRONEN: Olga Maurer

- 15 years at KRONEN: Eric Lefebvre, Andreas Hauer, Angela Mätz, Tobias Studer

- 10 years at KRONEN: Tobias Rose

The family company has been training young talents in a variety of commercial and technical professions for more than two decades, and several positions are still available for apprenticeships starting in September 2026.

KRONEN GmbH presents itself to current and future employees in its new video (German): www.kronen.eu/echtkronen

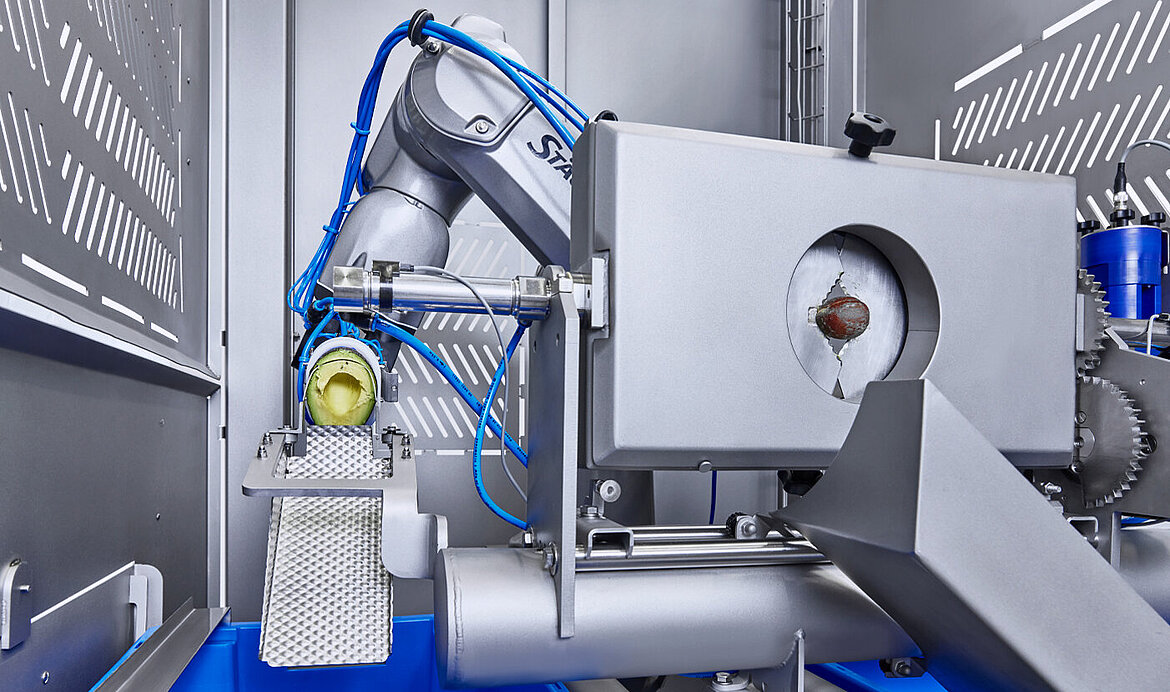

Research pays off: KRONEN is granted a patent for its avocado processing solution

Last year, KRONEN was granted a patent for the tools and methods that it developed to enable a robot to pit and peel avocados, allowing the sensitive fruit to be processed in a gentle, automated procedure. KRONEN developed the innovative solution in a research project in cooperation with the German Institute of Food Technology (DIL) and is the only system of its kind on the market.

In spring 2024, KRONEN delivered its first robotic solution for avocado processing. Over several weeks, the company Lazy Foods, a manufacturer of clean-label guacamole and avocado spreads based in the Netherlands, used the Robot Avocado Line to pit and peel avocados under real production conditions. The test phase for the automation of its avocado processing activities was a complete success.

KRONEN GmbH launches new solutions on the market every year. Last year, the Tona V cutting machine celebrated its premiere. The machine cuts fruit and vegetables into slices, segments or sticks with a capacity of up to 3,600 units per hour.

KRONEN on TV: a video report on the “take-and-bake doner kebab”

In 2024, the science TV show “Galileo” broadcast by the German television network ProSieben visited the brand-new production facility of the KRONEN customer Alzarro Dönerworld GmbH in Korbußen, Germany, which recently launched its “take-and-bake doner kebab” on the market. The kebab is sold in supermarkets and heated up by consumers in their own ovens.

To process the vegetables used in the kebab, the manufacturer integrated a multitude of KRONEN machines into its new processing line, for example a GS 10-2 belt cutting machine, a GEWA 3800V ECO washing machine and a KS-7 PLUS vegetable and lettuce spin-dryer.

Global demand for KRONEN solutions for processing salad leaves and vegetables

In summer 2024, an innovative “smart” processing line by KRONEN was successfully installed and put into operation at the facility of a major salad processing company in Northern Germany. The solution, in which the individual machines communicate with each other and are controlled from a central unit, facilitates the continuous gentle processing of delicate salad leaves with results of a consistently high quality.

Last year, a line for preparing, cutting and washing broccoli and cauliflower was delivered to the USA, enabling its recipient to process up to 6,000 units per hour. The US company supplies its fresh-cut products to customers such as restaurants, hotels, catering establishments, wholesalers and retailers.

What’s more, in autumn 2024, a new processing system for cutting, washing and drying cabbage, carrots, beet, iceberg lettuce, and other salad leaves was installed at a facility in Eitan, Israel. The line, which was developed by KRONEN especially for the customer, meets the strictest kosher requirements. It was designed for the production of various salad mixes, which are then packaged in bags and supplied to supermarkets, hotels, restaurants, and catering companies throughout Israel. The line can process up to 2,500 kg of iceberg lettuce and 4,000 kg of cabbage per hour.

A “Hidden Champion” in the Black Forest Power Region

A total of 44 companies were awarded the title of “Hidden Champion” at the general meeting of the business network nectanet in 2024. They were chosen to receive the title based on a scientific study conducted by the Fachhochschule Dortmund University of Applied Sciences and Arts. The “Hidden Champions” are selected based on criteria such as the market position and revenue of the companies.

Many of the award-winners are much larger than KRONEN GmbH – another reason why the award is particularly special for the company. “We are delighted and proud to have been awarded the title of ‘Hidden Champion’ in the Black Forest Power Region,” declared Stephan Zillgith. “The quality and safety of our machines and the satisfaction of our customers are our top priority, and we highly value our team of KRONEN employees, who help achieve this high level of excellence day after day. Their hard work pays off, and we are pleased to have been working successfully as a family company in our industry for more than 45 years.”

Digitalization and investments at the sites in Goldscheuer and Achern

KRONEN is continuously developing not only its food processing solutions but also its internal processes and working methods. A central aspect of these optimization measures is digitalization, which includes the increasing conversion of the company’s processes to production using digital channels. Since 2024, every employee in KRONEN’S production departments has had access to a PC workstation and, therefore, to 3D models of machines, technical drawings, important information and digital tools for precise and efficient documentation and communication. These digitalization measures not only improve efficiency but also lead to increased sustainability in production processes.

Last year, the KRONEN site in the German city of Kehl am Rhein also welcomed the construction of a new hall designed to ensure efficient production procedures and the high-quality processing of KRONEN machines. The hall acts as a logistics center between the various stages of work involved in building the machines. It provides a location in which the components and machines can be safely stored away from the elements and arranged in a system for the subsequent stages of work. As a result, it offers perfect conditions for the production of high-quality machines with long service lives.

At its WS Edelstahltechnik site in Achern, Germany, KRONEN has invested in expanding its range of machinery by purchasing an additional high-performance CNC turning machine with modern technology to extend its automation and production capacities at the location. The dual-spindle machine from the manufacturer Mazak is fitted with a short bar loading magazine for automatically loading raw material. WS Edelstahltechnik produces turned and milled parts with maximum precision and efficiency, not only for KRONEN’s own machines but also for other mechanical engineering companies.

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines, and high-tech processing facilities for the fresh-cut industry. The product portfolio of KRONEN and its partners covers fruit, vegetable and salad leaf processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging.

KRONEN additionally offers machines for the processing of meat and fish, special vegan products, baked goods and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide and supplies its products to more than 120 nations all over the globe.

With more than 45 years of experience in food technology, KRONEN prides itself on its quality awareness and constantly strives to achieve the best possible solutions in its day-to-day work. The machine manufacturer focuses on taking a sustainable, holistic approach toward the hygienic, reliable and resource-friendly production of fresh foods. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.