In this interview, Eric Lefebvre provides an insight into the constant further development of KRONEN’s hygiene concept and how its solutions are adapted based on the findings of new technical developments and current research.

When it comes to processing foods, optimal hygiene is a prerequisite. This also, of course, applies to our food machines used in processing activities. The company KRONEN GmbH has been working in the food processing industry for more than 40 years. Ever since KRONEN was founded, we have constantly developed our hygiene concept and continuously adapted our machines and processing lines according to the findings of the latest technical developments and current research in terms of hygienic design. KRONEN is now presenting the latest updates to its hygiene concept, demonstrated on its new HEWA 3800 HELICAL washing machine as an example.

The company KRONEN GmbH, which is based in the German town of Kehl am Rhein, supplies its products to more than 120 countries and is well known for its high quality standards all over the globe. The company has been working in the food processing industry for more than 40 years. Eric Lefebvre has been the Technical Manager of KRONEN since 2010 and additionally a Managing Partner since 2018. In his role, he is also responsible for the company’s hygiene strategy and manages a multitude of research projects conducted in close cooperation with universities, research establishments and the industry.

Since when has KRONEN been exploring the topic of hygiene?

Eric Lefebvre: “Hygiene has been an integral part of KRONEN GmbH ever since day one. It is one of the most essential requirements that the machines and systems used for food processing are expected to meet. Our high quality standards not only help our customers using these solutions to ensure the consumer safety of their products but also serve to secure the freshness and long shelf lives of the products processed. In the more than 40 years in which KRONEN has been operating in the food processing industry, we have learned a great deal about hygiene. We constantly follow the latest developments in terms of technology and science and remain in close contact with relevant experts. In 2017, this led to the establishment of our own hygiene regulations, which specify the special requirements for hygiene processing and hygienic design.”

What are the concrete benefits of hygienic design for food processing companies?

“An important aspect that we have continuously optimized is guaranteeing the simple, efficient cleaning and hygienization of our machines. This is where hygienic design plays a decisive role. Another essential factor is good accessibility when cleaning the machines and the option of dismantling parts of the machine. Time plays a central role in the production activities of food processors. We therefore aim to maximally reduce the time and effort involved in cleaning our machines while ensuring optimal, thorough hygiene at the same time.”

Does a hygiene concept provide an advantage in economic terms?

“Of course – if you reduce the cleaning and hygienization cycle, you can also make some savings. You not only save the time required for the cleaning process; you can also benefit from needing less water, fewer chemicals and less energy for the cleaning. Alongside the fact that hygienic, safe food production is an absolute must that needs to be ensured, such factors also make a hygiene concept a clear economic benefit too. In turn, the fact that we can use it to support our customers on a sustained basis gives us a competitive advantage. Our solutions represent high quality and maximum hygiene, which are valued by our customers all over the globe.”

What is the current status of your hygiene-related developments?

“Our current approach to hygiene involves discussing every machine and every new development and examining how we can further improve its hygienic design. Our quality management system has been successfully certified in accordance with the ISO standard 9001:2015 since 2021. This also helps us with regard to hygiene: processes are firmly defined and are checked and optimized on an ongoing basis. We therefore have set requirements that we have to fulfill when creating a machine or line. What’s more, we have been researching completely new solutions for years. We want to be a pioneer that offers the industry innovative solutions that it has never seen before. To achieve this, we work in close cooperation with our customers and partners from the world of research.”

Do you have an example?

“The research project ‘SPLASH’ focuses on an innovative washing procedure for freshly cut lettuce on the basis of non-thermal plasma technology, with the aim of increasing product safety, quality and sustainability. Together with our partner Citrosol, we introduced the hygienization system Citrocide to the market. This new and unique washing system combined with a measuring and dosing unit is an innovative alternative to chlorine-based disinfection and optimizes water use. It is suitable for hygienically washing fruit, vegetables and salad leaves. Another example: Together with sterilAir, we were the first company in the industry to offer inline treatment of the recirculated water in our washing machines using UVC solutions from sterilAir.”

Are there other examples that show developments in terms of hygienic design?

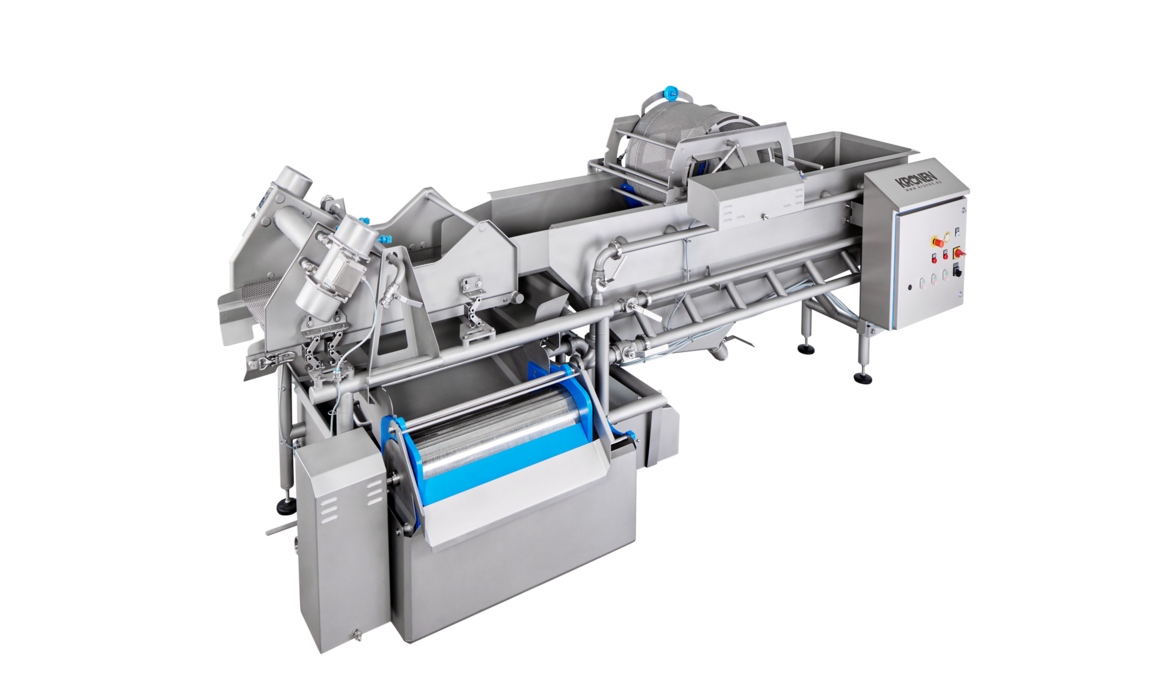

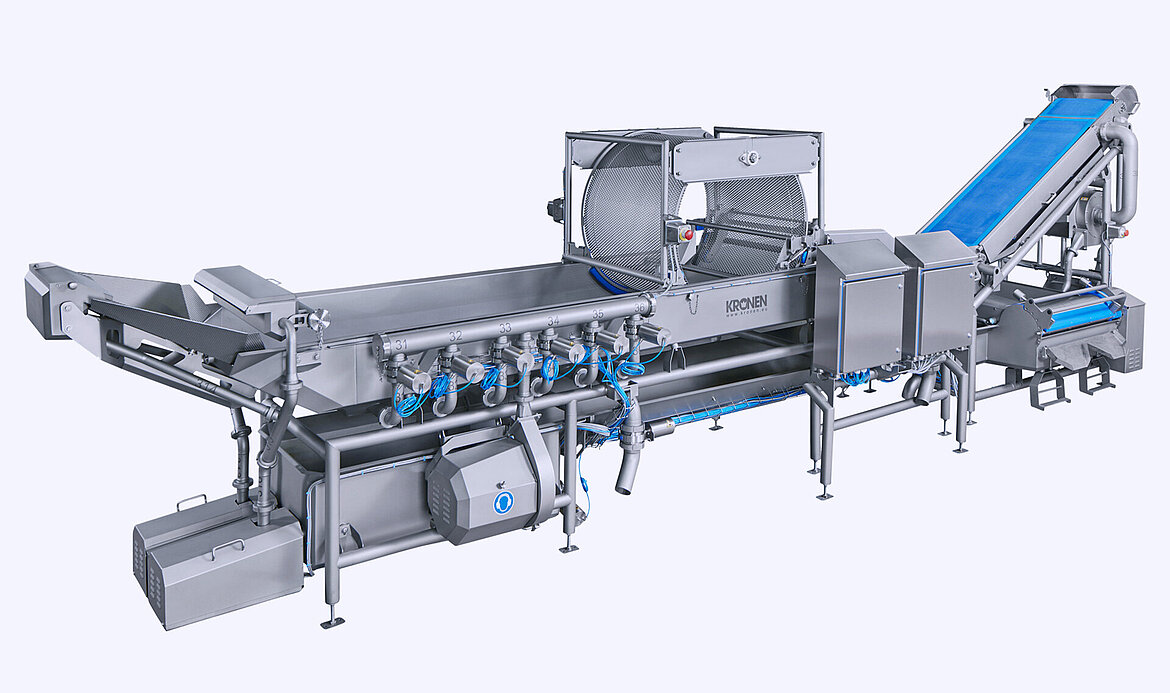

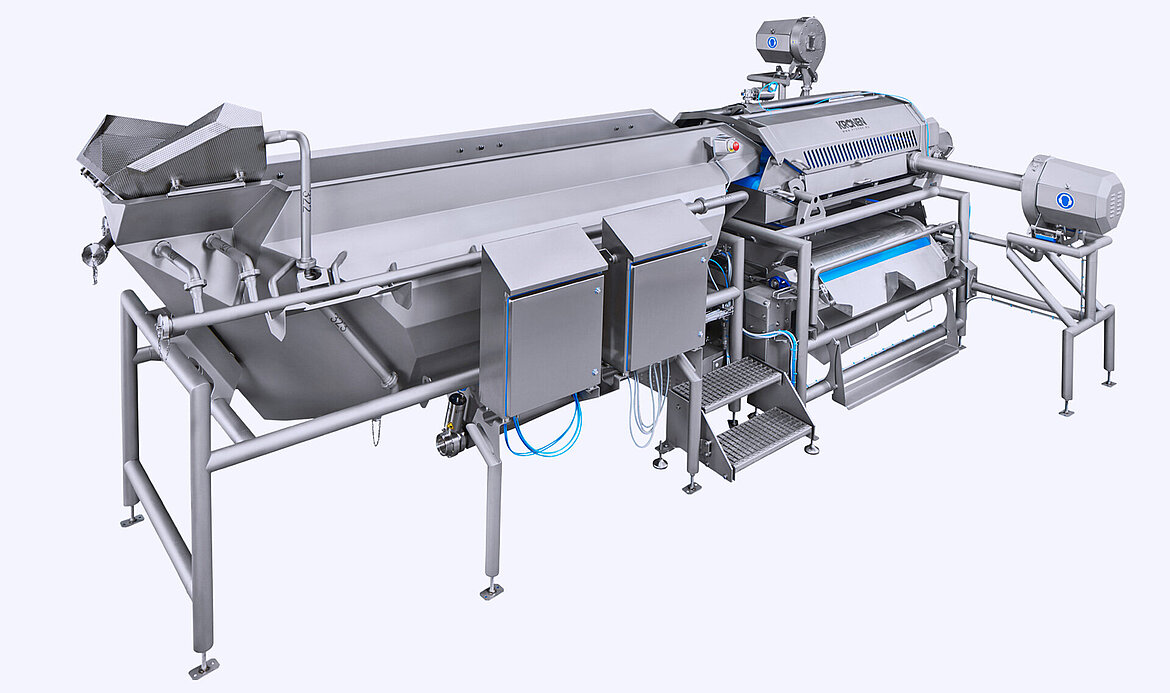

“Here, virtually all of our machines can be used as examples. Take the latest developments in the area of washing, for instance: the HEWA 3800 HELICAL washing machine for lettuce, vegetables, fruit and other foods has been optimized in terms of hygiene and easy cleaning. The design concept also ensures maximum hygiene, for example the fact that the machine has no horizontal surfaces whatsoever, thus allowing the water to optimally discharge. What’s more, all edges are designed to avoid the formation of biofilm. This enables us to minimize the risk of contamination and cross-contamination. Effective access to all critical areas of the machine also plays an essential role.”

What do you mean when you say “critical areas”?

“It’s all about cleaning the machine effectively, namely fully and thoroughly while saving time. The HEWA 3800 can be completely dismantled for rapid and thorough cleaning. The GEWA AF pre-washing machine is another good example: to enable quick cleaning, everything inside the wash tank has an open design and there are no air pipes. The pipes of the GEWA AF can also be completely disassembled. To clean the pipe system without needing to dismantle it and to ensure the lowest possible water consumption, an optional ‘Clean in Place’ system can be integrated into the machine. This is also possible with the GEWA XL, which can additionally be completely disassembled to guarantee easy access to the entire machine.”

What are your visions for the future when it comes to KRONEN’s hygiene concept?

“It is important that we always keep learning, developing and making progress rather than simply settling for what we have already achieved. I think that is what truly defines our team at KRONEN. For 40 years, our contact with the industry, the world of research, and groups of experts such as the EHEDG has helped us to gain new insights in the areas of technology and hygienic design and to implement this knowledge in our development activities. To further intensify this progress, among others, we have now officially joined the EHEDG, a group of experts with which we have already been in close contact for many years. Our aim is to develop solutions that will benefit our customers. When doing so, we want to be sustainable: saving resources and increasing safety and productivity therefore both play an equally essential role in terms of both sustainability and our hygiene concept.”

About KRONEN GmbH

KRONEN is a family-managed, globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product program of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging. KRONEN additionally offers technical solutions for meat and fish, baked goods, ready meals, dried and frozen products and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representations in over 80 countries worldwide, and supplies its products to more than 120 nations all over the globe.

With more than 40 years of experience in food technology, KRONEN preserves traditional values such as quality awareness and relies on a sustainable, holistic approach for the hygienic, reliable production of healthy food. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry.

A selection of pictures you can find below (click right mouse button and save the picture).

Do you need more or a different type of material? We are happy to help. Your contact: presse@kronen.eu, T +49 (0)7854 9646-160 / -161.