Small package sizes for the portioned packaging of food products

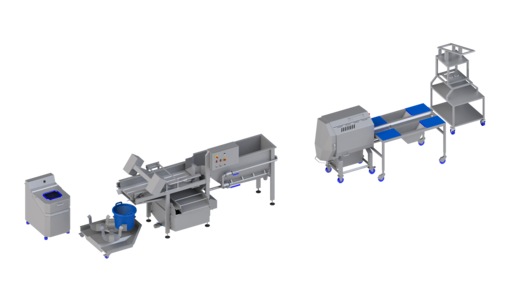

With an adjustable bag width from 40 to 160 mm and unlimited bag length, the MINI can be used to produce packaging for a wide range of products. Food products, for example (cut) vegetables, fruits, lettuce or nuts, as well as sauces and dressings and even non-food products, are efficiently packaged in portions. Manual filling of the packaging machine is also possible. In the standard configuration, the MINI produces pillow bags; optionally, self-standing bags can also be produced.

The mobile packaging machine from KRONEN's partner GKS Packaging B.V. is suitable for both high-care and low-care production areas. Thanks to its small footprint and low height, it can be combined with many dosing systems and used flexibly in smaller production areas and industrial environments.

The modular and compact yet open construction makes cleaning and maintenance easier. Some components of the machine are made from recycled ocean plastic.